عنا

مرحبا هل يمكنني مساعدتك؟

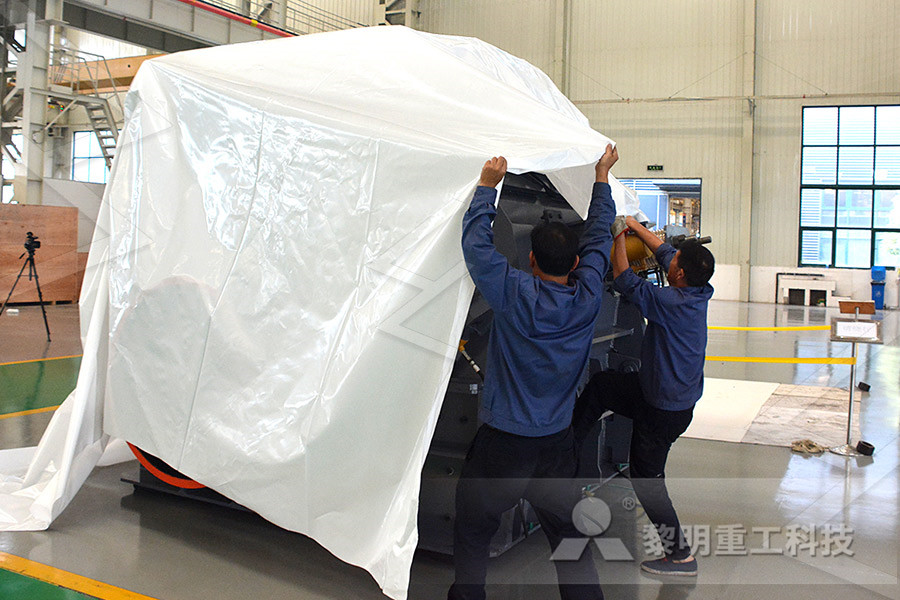

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

hydraulic cone crusher operating principle

2023-03-05T22:03:01+00:00

Cone Crusher SpringerLink

2023年5月3日 It was developed by AllisChalmers (AC) Company in the 1940s, so it is usually called AC cone crusher Singlecylinder hydraulic cone crusher has the same 2017年9月24日 Working principle: Technical data: When cone crusher begins to work, the electro motor drives the eccentric sleeve through the spring coupling, drive shaft and a Operating Instruction HYDRAULIC CONE CRUSHER2023年2月23日 The hydraulic system in a cone crusher is responsible for controlling the various components of the crusher, such as the feed and discharge ports, the adjustment ring, and the mainframe The system Understanding the Cone Crusher Working

A review of modeling and control strategies for cone crushers

2021年8月15日 The initial exploration of the basic operation principles of cone crushers was reported in Evertsson, 1995, Evertsson and Bearman, 1997, the breakage 2 天之前 Hydraulic Cone Crusher Operating Principle AF cone crushers adopt the layered materials selection The crushing cavity is filled with feeding material Since the materials Hydraulic Cone Crusher AF Minerals Equipment2015年5月13日 Principle of a cone or gyratory crusher +17 For a fixed point in the chamber the distance between mantle and concave varies cyclically with time Figures uploaded by Magnus Evertsson(PDF) Cone Crusher Performance ResearchGate

Cone Crushers (Parts of a Cone Crusher) Explained

The spring cone crusher design is able to pass uncrushable materials eg tramp metal, through the crushing cavity by using springs The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of 2022年12月12日 The main parts of the cone crusher are transmission device, crushing cone, bowlshaped bearing, frame and hollow eccentric shaft Besides, the size of the What Is the Cone Crusher Working Principle?2021年11月1日 The basic operating principle and general production objectives of a cone crusher are also explained Section 3 formulates the control problem from the economic Size reduction control in cone crushers ScienceDirect

Cone Crushers (Parts of a Cone Crusher) Explained

The spring cone crusher design is able to pass uncrushable materials eg tramp metal, through the crushing cavity by using springs The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of 2022年4月1日 cone, Gyradisc NP Impact Crusher Vertical Shaft Impact Crusher Recommended training days per equipment type Theory training Classroombased course which covers basic operation principles, operator interface, safe use of Outotec crushers as well as aftersales support This course is intended for operators, Training Academy Crusher product training 2015年5月13日 The basic operating principle of a cone crusher is shown in Figure 4 The properties, ie size Hydraulic pressure Product size Product shape Product strength XXXX 00 X 00 XXXXXXXXX(PDF) Cone Crusher Performance ResearchGate

Principles of Mechanical Crushing 911 Metallurgist

2016年1月12日 Crusher Modeling Prediction of: zProduct Particle Size Distribution zCapacity zCrushing Force zHydraulic Pressure zPower Draw Design and Operation zComputer Calculation Model of Cone Crushers zUtilize the crusher as efficient as possible zEnergy efficient crushing zRobust performance during the entire wear part life Designed for your needs, ® HP6™ cone crusher is safe and easy to maintain Fast and easy access to all the main components from the top, dualacting hydraulic cylinders, and no backing material significantly reduce downtime and are more environmentally friendly ® HP6™ cone crusher is engineered to ensure maximum operator ® HP6™ cone crusher Gyrating or cone crusher: The gyratory crushers are equipped with a hydraulic setting adjustment system, which adjusts css and thus affects product size distribution Depending on cone type, the css setting can be adjusted in two ways 9311 Jaw Crusher Operating Principles Fixed and movable jaw plates are the two main Crusher an overview ScienceDirect Topics

Working Principle of Crushers 911 Metallurgist

2016年2月17日 The crusher head is at the moment in the closeside position Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1” Note that the length of line “1″ from concave to openside head position, is the same as that of 2006年8月30日 Hydroset pressure and power draw were read off the control panel of the crusher once every day When the inlet bin of the crusher is entirely filled with rock material, the crusher is said to be choke fed, and this is the preferred way to operate a cone crusher Readings were taken during normal operation of the crusher, ie choke fed conditionsDevelopment of wear model for cone crushers ScienceDirectAdvanced crushing dynamics leads to more work per cycle ® MP1000 cone crusher increases power draw so that will lead to an increase in capacity, and a higher powertoproduction ratio giving energy efficiency too So ® MP1000 cone crusher not only performs for you, but also performs to help with a costsaving operation® MP1000™ cone crusher

Understanding Cone Crusher Parts Names, Functions, and

2023年2月22日 The following are some of the types of cone crusher parts: Mainshaft and head center: The mainshaft is a rotating component that connects the mantle to the motor The head center is a stationary part that supports the mantle and distributes the crushing forces These components are critical for the proper functioning of the cone crusher2009年2月1日 The crusher is an Allis Chalmers 36” Hydrocone equipped with a medium chamber The reason why a fine chamber is not used is that theValidation In order to perform a fair comparison between crusher operation with a constant setting and crusher operation with the algorithm, the two methods of operation were alternated, see Fig 8Algorithm for dynamic cone crusher control ScienceDirect2012年8月15日 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing Cone Crusher Working Principle Animation

Crushing Principles of Mechanical Crushing 911

2016年1月11日 Operating Principal • In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber • The relative amounts of IPB and SPB depends on factors like chamber design, crusher geometry, speed, css, eccentric throw, and others SPBOverview of size reduction of raw materials of the cement industry Vipin Kant Singh, in The Science and Technology of Cement and Other Hydraulic Binders, 2023 4234 Fixedspindle type of gyratory crusher In this crusher, an eccentric sleeve is inserted between the fixed vertical shaft and the movable vertical cone (Fig 43 B)By rotating this eccentric Gyratory Crusher an overview ScienceDirect TopicsLess downtime, more confidence ® HP500™ cone crusher delivers less downtime and increased operator confidence Dualacting hydraulic tramprelease cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed The double accumulator combination provides better reactivity of the hydraulic system® HP500™ cone crusher

Crushing Principles of Mechanical Crushing 911

2016年1月12日 Operating Principal In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber The relative amounts of IPB and SPB depends on factors like chamber design, crusher geometry, speed, css, eccentric throw, and others SPB IPBGenerally speaking, spring cone crusher cost starts from 23,880 USD, singlecylinder hydraulic cone crusher starts from 58,310 USD, mutlicylinder hydraulic cone crusher starts from 61,490 USD The prices above just include the crusher machine, they don’t include other fees such as transportation etc TypeCone Crusher For Sale In Indonesia Price from $23,880 12 Features ® HP4™ cone crusher is designed with safety, simplicity and ecoefficiency in mind It is a robust rock crushing machine used especially in secondary, tertiary, and quaternary crushing stages in aggregates production and mining applications HP4™ is part of the latest generation of cone crushers with improvements such as ® HP4™ cone crusher

Crushers All crusher types for your reduction needs

The cone crushers are equipped with a hydraulic setting adjustment system, which adjusts closed side setting and thus affects product gradation Depending on cone crusher, setting can be adjusted in two ways and the continuous operation principle (while the reciprocating motion of the jaw crusher produces a batch crushing action) The 2023年3月14日 Working Principle When a HST Single Cylinder Hydraulic Cone Crusher works, driven by the motor, the transmission shaft rotates under the action of belt pulley and triangular belt Next, the transmission shaft drives the eccentric sleeve to make it rotate around the axis Meanwhile, the eccentric sleeve forces the movable cone to do pendular HST Single Cylinder Hydraulic Cone Crusher Mill Crusher2021年4月1日 5 It has a spring safety system and overload protection capability, which can effectively discharge the choking iron and improve the ability of the cone crusher to cope with emergencies; 6 The The detailed explanation of advantages and disadvantages of the cone

Crushing Principle, Gear Wear and Solution of Cone Crusher

2020年1月13日 The hydraulic cone crusher handles secondary crushing in the production line, and specializes in processing of mediumhard materials During the operation of the equipment, there will be problems such as tooth cracking, wear, jamming, and undercutting of the umbrella teeth, which will not only affect production, but also Cause direct or Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the Cone Crusher an overview ScienceDirect TopicsUnder the condition of the constant crushing chamber, the maximum feeding size and productivity can keep constant, it has higher output, longer liner life, and lower operating costs Its mainframe weight is 5700 to 36,300 kg, the weight of Symons cone crusher is 9980 to 43,270 kg, and its volume and weight are smaller than Symons cone crusherThe Models And Parameters Of Cone Crusher

Prediction of worn geometry in cone crushers ScienceDirect

2003年12月1日 Fig 2 shows the operating principle of a cone crusher The motor turns the eccentric with a bevel gear The mantle is suspended on a spherical thrust bearing at the bottom, a cylindrical bearing in the eccentric and a spherical bearing at the top The close side setting is controlled by a hydraulic system that can lower or raise the 2019年12月5日 The singlecylinder hydraulic cone crusher has a new crusher structure, optimized laminated crushing cavity type, and a fully intelligent automation control system In general, it can be widely used in medium crushing, fine crushing, and ultrafine crushing operations The working site of the cone crusher in IndiaWhat Is A Hydraulic Cone Crusher? HongXing Machinery2016年1月1日 The gape of the secondary crusher should be 11 times larger than the largest particle in the feed and the feed should have 80% less than 70% of the feed opening of the crusher Reference to manufacturer’s data on performance of cone crusher sizes is useful Table 57 indicates the performance of cone crushers operating in open circuit Gyratory and Cone Crusher ScienceDirect

Energy considerations in compressive and impact crushing

2008年8月1日 In a Sandvik crusher, the hydraulic pressure is referred to as the “hydroset pressure” The crusher is supplied with a control system that monitors performance and protects the crusher from overload and tramp metal Download : Download fullsize image; Fig 1 Operating principle of a cone crusher2021年11月11日 This paper reports the calibration and validation of a cone crusher model using industrial data Usually, there are three calibration parameters in the condensed breakage function; by contrast, in this work, every entry of the lower triangular breakage function matrix is considered a calibration parameter The calibration problem is cast as Calibration and Validation of a Cone Crusher Model with 2020年3月26日 The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, granite, basalt, cobblestone, marble, limestone and so on The Hydraulic Cone Crusher is popular to be used in high automatic crushing line which has strict requirement for finished products’ shape and ratioHydraulic Cone Crusher PDF PDF Mechanical Engineering

How Impact Crushers Work: A Comprehensive

2023年3月11日 Crushing Equipment / March 11, 2023 / 5 minutes of reading An impact crusher is a machine used to crush materials by impact energy It works by feeding the material into a rotating rotor, which is 2023年7月31日 A cone crusher is crucial, especially in aggregates and mining industries It plays a role in crushing hard rocks into smaller rocks for further processing Understanding how a cone crusher operates is essential to optimize its performance to achieve effective crushing This article will delve into the components of the cone crusher, its application, How Does A Cone Crusher Work: Understanding The 2023年2月24日 Hydraulic cone crushers are powerful machines that are widely used in mining, construction, and other industries In this article, we will explain the mechanics of hydraulic cone crushers, their types, applications, and maintenance requirements We will also address some frequently asked questions about these machines to help you make Everything You Need to Know About Hydraulic Cone Crusher

SINGLE CYLINDER HYDRAULIC CONE CRUSHER

2020年8月3日 Operating Principle 单缸圆锥破碎机工作时:电机带动破碎机的小齿轮,小齿轮带动大齿轮,大齿轮组件(大齿轮、大齿轮架、偏心钢 套)带动偏心套组件(偏心缸套、偏心铜套)和主轴组件(主轴、内锥、内锥衬板)以理论垂直线为中心,在铜衬套内Hydraulic cone crusher is developed as highenergy cone crusher by introducing German latest technology The Hydraulic crusher does not only improve production capacity and crushing efficiency, but also expands application scope: it can provide unequaled crushing performance in each kind of medium crushing, fine crushing and ultrafine crushing Hydraulic Cone Crusher Mobile Crusher Philippines2022年11月3日 The hydraulic system on the cone crusher is mainly used to ensure the normal operation of the equipment and adjust the size of the discharge opening Adjust the discharge opening: During normal Maintenance of Cone Crusher Hydraulic System LinkedIn

fr/principle cone crusher pdfmd at main hedaokuan/fr

Contribute to hedaokuan/fr development by creating an account on GitHub2009年2月1日 In order to perform a fair comparison between crusher operation with a constant setting and crusher operation with the algorithm, the two methods of operation were alternated, see Fig 8 Each method is given n alternate number of test periods with the length Δt s at a time Download : Download fullsize image; Fig 8Algorithm for dynamic cone crusher control ScienceDirectThe spring cone crusher design is able to pass uncrushable materials eg tramp metal, through the crushing cavity by using springs The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of Cone Crushers (Parts of a Cone Crusher) Explained

Training Academy Crusher product training

2022年4月1日 cone, Gyradisc NP Impact Crusher Vertical Shaft Impact Crusher Recommended training days per equipment type Theory training Classroombased course which covers basic operation principles, operator interface, safe use of Outotec crushers as well as aftersales support This course is intended for operators, 2015年5月13日 The basic operating principle of a cone crusher is shown in Figure 4 The properties, ie size Hydraulic pressure Product size Product shape Product strength XXXX 00 X 00 XXXXXXXXX(PDF) Cone Crusher Performance ResearchGate2016年1月12日 Crusher Modeling Prediction of: zProduct Particle Size Distribution zCapacity zCrushing Force zHydraulic Pressure zPower Draw Design and Operation zComputer Calculation Model of Cone Crushers zUtilize the crusher as efficient as possible zEnergy efficient crushing zRobust performance during the entire wear part life Principles of Mechanical Crushing 911 Metallurgist

® HP6™ cone crusher

Designed for your needs, ® HP6™ cone crusher is safe and easy to maintain Fast and easy access to all the main components from the top, dualacting hydraulic cylinders, and no backing material significantly reduce downtime and are more environmentally friendly ® HP6™ cone crusher is engineered to ensure maximum operator Gyrating or cone crusher: The gyratory crushers are equipped with a hydraulic setting adjustment system, which adjusts css and thus affects product size distribution Depending on cone type, the css setting can be adjusted in two ways 9311 Jaw Crusher Operating Principles Fixed and movable jaw plates are the two main Crusher an overview ScienceDirect Topics2016年2月17日 The crusher head is at the moment in the closeside position Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1” Note that the length of line “1″ from concave to openside head position, is the same as that of Working Principle of Crushers 911 Metallurgist

Development of wear model for cone crushers ScienceDirect

2006年8月30日 Hydroset pressure and power draw were read off the control panel of the crusher once every day When the inlet bin of the crusher is entirely filled with rock material, the crusher is said to be choke fed, and this is the preferred way to operate a cone crusher Readings were taken during normal operation of the crusher, ie choke fed conditionsAdvanced crushing dynamics leads to more work per cycle ® MP1000 cone crusher increases power draw so that will lead to an increase in capacity, and a higher powertoproduction ratio giving energy efficiency too So ® MP1000 cone crusher not only performs for you, but also performs to help with a costsaving operation® MP1000™ cone crusher 2023年2月22日 The following are some of the types of cone crusher parts: Mainshaft and head center: The mainshaft is a rotating component that connects the mantle to the motor The head center is a stationary part that supports the mantle and distributes the crushing forces These components are critical for the proper functioning of the cone crusherUnderstanding Cone Crusher Parts Names, Functions, and