عنا

مرحبا هل يمكنني مساعدتك؟

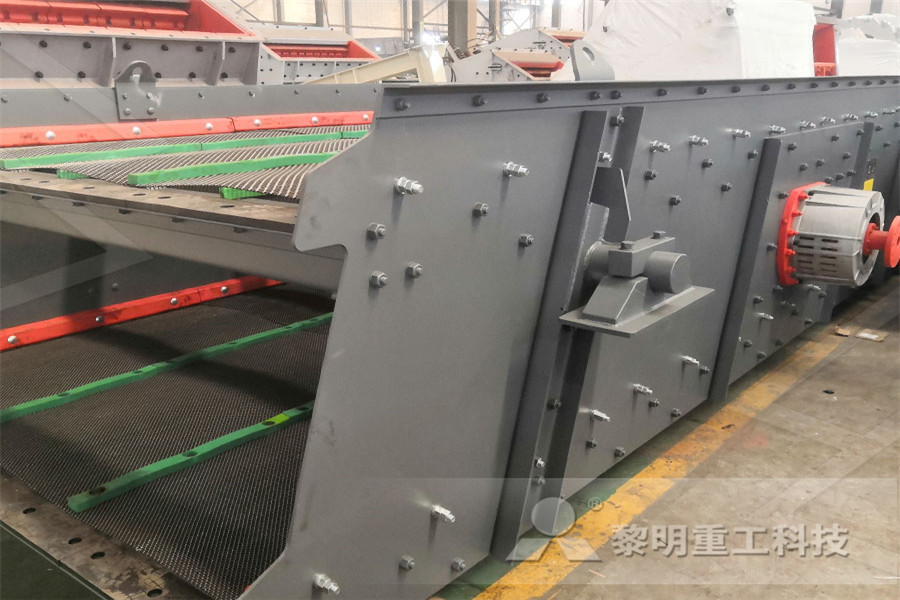

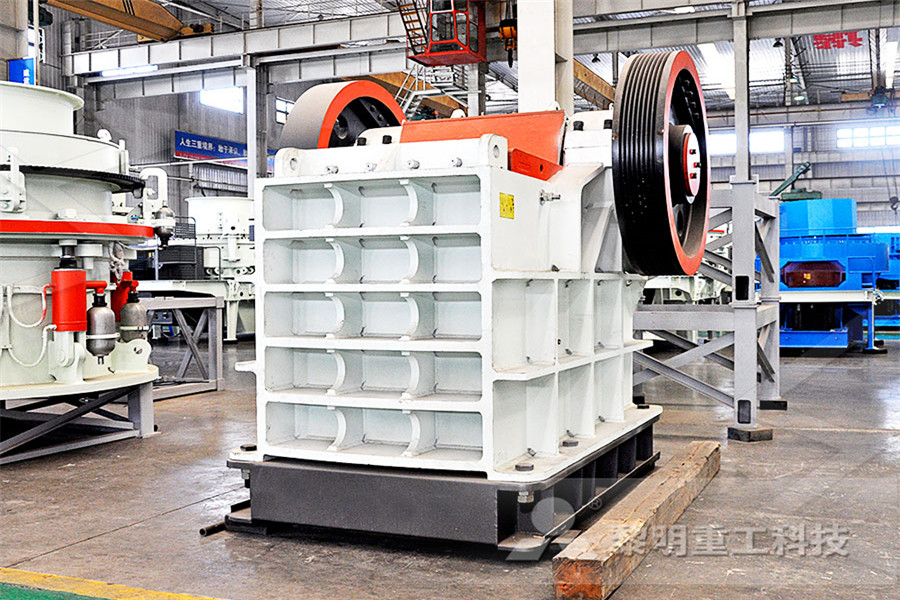

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

manganese oxide processing equipment

2022-03-10T19:03:53+00:00

Manganese Ore Processing Plant and Equipment

2020年3月6日 The process of processing manganese oxide ore is generally crushing the ore to 60mm or 100mm, and then classifying, coarse grade particles are sent to jig sorting, and fine grade particles are 2023年5月30日 Reductive roasting using coal as reducing agent is the most commonly reductive roasting technique in treating manganese oxide ores 10 However, it often A Process for Extraction of Manganese from Manganese Oxide 2023年10月29日 This review comprehensively summarized synthesis methods, modification enhancement mechanisms, activation mechanisms and influencing factors Manganese oxide and derivativemodified materials in

Manganesebased layered oxides for

The everincreasing demand for highenergydensity electrochemical energy storage has been driving research on the electrochemical degradation mechanisms of highenergy cathodes, among which manganesebased Manganese oxides have enabled a wide range of technologies including oxygen evolution catalysts, lithium ion batteries, and thermochemical water splitting However, the variable Phase formation of manganese oxide thin films using pulsed polymorphism of manganese oxides make it difficult to find the processing conditions to target a particular phase of manganese oxide Targeted synthesis requires a more Phase formation of manganese oxide thin films using

Manganese dioxide nanoparticles: synthesis, application and

2020年10月13日 Abstract In recent days, manganese oxide nanoparticles (MnO 2 NPs) have intrigued material science researches extensively due to its wide range of 2023年2月4日 Science in Semiconductor Processing ( IF 41) Pub Date : , DOI: 101016/jmssp2023 近年来,储能器件,特别是超级电池器件,因其高能量密 锰(硫化物/氧化物)基电极材料在超级电池装置中的进步 2020年9月1日 Last Updated: 25 Jul 2023 PDF The efficient utilization of manganese dioxide (MnO2) ore is essential for the sustainable development of manganese (Mn) (PDF) From laboratory research to industrial application: A

How is manganese extracted? LinkedIn

2022年12月29日 Electrolytic method: This method involves dissolving the manganese ore in an electrolyte solution and passing an electric current through the solution The manganese is then extracted from the 2022年4月28日 Because of the nanoscale tunnel constructed by the active MnO octahedron in cryptomelane, cryptomelanetype manganese oxides have high activity in the oxidation of several volatile organic Manganese Oxide Minerals from the Xiangtan 2023年4月10日 The complete processing flow of manganese ore mainly includes five steps: crushing, washing, grinding, dressing, and drying Next, I will introduce the detailed manganese ore processing production line to you 1 Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves 5 Easy but Efficient Steps to Realize Manganese Ore Processing

The Complete Book on Ferroalloys Semantic Scholar

2017年10月27日 10 PRODUCTION PROCESS OF FERRO SILICON Raw Materials Production of Ferrosilicon, Silicon Metal and Silicocalcium Ferromanganese and Manganese Alloys Refining of Ferrosilicon Introduction Processes for the Refining of Ferrosilicon Solid/Liquid Oxide Method Oxidising Treatment with Gaseous Oxygen/Enriched 2016年4月27日 Concentration—Gravity Methods of treating Manganese Ore The mill feed, drawn from one or more bins, is sampled at the ore feeder discharge to obtain a composite sample for mill control After elevating, a vibrating screen separates the feed into sizes best suited for the Improved Harz Type Jigs and Selective Mineral JigsManganese Ore Processing 911 Metallurgist3 小时之前 • List of Machinery Provider Manganese Oxide, a chemical compound with the formula MnO, stands as a significant player in both industrial and natural processes Manufacturing Process, Plant Manganese Oxide Manufacturing Plant Project Report 2023:

Manganese processing Extraction, Uses Benefits Britannica

manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such as sulfur and oxygen and adds important physical properties to the metal2019年3月11日 At present, the technological process of treating manganese oxide ore in our country usually breaks the ore to 60 mm or 100 mm, then divides the ore into groups, jigs the coarse grade and shaker Beneficiation and Processing Technology of Manganese Ore2019年7月15日 Gravity Separation Process back to top Gravity separation process is a beneficiation method according to the difference in density of minerals, whose process can be carried out in a medium such as water or air The density of common manganese oxide minerals ranges from 3,700 to 5,000 kg/m3, the density of manganese carbonate How to Extract the Manganese Ore? Miningpedia

Metals Free FullText Novel Process of

2022年2月23日 Manganese is the fourth most widely used metal after iron, aluminum, and copper It is used in numerous fields, such as ferrous and non–ferrous metallurgy, batteries, the chemical industry, agriculture, and 2 天之前 the Analyst Spring 2013 Volume 20 Number 2 ManganeseRelated Corrosion and Fouling In Water Systems By Wayne H Dickinson, PhD and Christopher L Wiatr, PhD, BuckmanManganeseRelated Corrosion and Fouling In Water 2023年10月25日 JXSC manganese ore process and equipment can separate various components of ore, including crushing, washing, screening, gravity separation, magnetic separation and flotation processes, etcAfter Manganese Processing Plant, Equipment Mineral

5 Commonly Used Manganese Processing Methods Mining

2021年6月29日 The impurity minerals are mainly Fe2O3, a highvalent iron oxide When the manganese oxide ore is reduced, the weakly magnetic Fe2O3 in the ore is reduced to the magnetic oxides Fe3O4, and γFe2O3 The magnetic separator can be used to separate manganese and iron, which improves the manganese grade of the manganese ore At Fig 1 Phase identification for a manganese oxide combinatorial library deposited from a Mn 2 O 3 target at a partial pressure of oxygen of 10 −3 torr and a total chamber pressure of 10 −2 torr, at substrate temperatures from 550 °C to 250 °C: (a) Raman spectroscopy results All scans show peaks consistent with the Mn 3 O 4 phase, but complementary FTIR (Fig Phase formation of manganese oxide thin films using pulsed 2021年11月30日 Most manganese sulfate is produced by the processing of manganese ore [5,6] The two main forms of manganese ore that can be mined from the earth are rhodochrosite (MnCO 3) and pyrolusite (MnO 2) Considering the rapid depletion of carbonate ore, the extraction of manganese from manganese oxide ore has drawn Preparation of manganese dioxide from lowgrade

Manganese sulfate bottleneck looms over US, European EV

2023年1月24日 China's control of global manganese processing capacity could lead to a supply bottleneck for US and European batterymakers by 2030 [original equipment manufacturers]," said Matthew James, is also closely watching developments in alternative battery chemistries such as solidstate and lithiumnickelmanganese oxide To improve the direct alloying of manganese ore in steelmaking, the decomposition and carbon reduction of manganese ore was studied using a differential thermal analyzer and resistance furnace The remaining material after manganese ore decomposition at 1,600 °C was a mixture of 43 % MnO, 40 % MnSiO 3 and FeO, and 17 % MnSiO 3 The Manganese Ore Decomposition and Carbon Reduction in 2022年2月23日 Manganese is the fourth most widely used metal after iron, aluminum, and copper It is used in numerous fields, such as ferrous and non–ferrous metallurgy, batteries, the chemical industry, agriculture, and animal husbandry [1,2,3]Manganese carbonate and oxide ores are two primary resources for extracting MnMetals Free FullText Novel Process of Reduction Roasting Manganese

Everything to Know About the Manganese Mining Industry

2022年3月20日 Manganese uses in industry According to the Proceedings of the National Academy of Sciences of the United States of America (PNAS) approximately 8090% of all manganese is consumed by the steel industry On average, steel contains around less than 06 weight percent of manganese, in particularly high strength steels this might exceed 2022年9月23日 The cyclic stability of the MnOx cathodes for rechargeable zinc ion batteries have substantial obstacles due to Mn3+ disproportionation produces Mn2+ caused by Jahn Teller lattice distortion effect in the Bulkphase and interface stability strategies of binary oxide processing window and for targeting a specific metal oxide phase24,25 In this work, the influences of substrate temperature, target composition, total deposition pressure, and the partial pressure of oxygen on manganese oxide phase formation are investigated using combinatorial PLD deposition from MnO, Mn 2O 3 and MnO 2 targetsPhase formation of manganese oxide thin films using

IOP Conference Series: Materials Science and

Product of carbonate manganese ore thermal processing 39,5 47,5 51,5 36,0 45,5 Liquid glass 4,0 5,0 5,5 4,0 5,5 During sintering of the briquettes of the proposed composition, manganese reduction from aluminum oxide and silicon occurs at high speed as well as interreacting of Al2O3 and SiO2 which are resulted from the reaction2022年2月2日 Manganese is a greywhite metal resembling iron Manganese is used extensively to produce a variety of important alloys and to desulfurize and deoxidize steel Manganese is also in many welding rods and filler metals to promote hardness Manganese oxide fume is one type of potentially dangerous welding fume that is formed when Manganese: A Welding Fume that may be a Threat to 2021年7月11日 The manganese oxides have been broadly studied at present for the removal of heavy metal ions of model water or wastewater due to its features, such as due to its nanometric particle size, geometric shape of the particles, crystal structure, high specific surface area, and specificity This chapter focuses on how the different synthesis Manganese Oxides: Synthesis and Application as Adsorbents

Nanostructured Manganese Oxides in Supercapacitors

2016年7月19日 In the established charge storage mechanisms, a redox reaction between the III and IV oxidation states of Mn ions occurs []As Mn is a transition metal element, there are several types of manganese oxide existing as a variety of stable oxide, and these include manganese (ΙΙ) oxide (MnO), manganese (ΙΙ, ΙΙΙ) oxide (Mn 3 O 4), manganese 2010年9月3日 The temperature at which the manganese oxide concentration in the slag was reduced below 10 wt pct can be assigned to the top of the coke bed in the silicomanganese furnace This temperature was in the range 1823 K to 1883 K (1550 °C to 1610 °C) In the prereduction process, higher manganese oxides were reduced to Ore Melting and Reduction in Silicomanganese Production2021年2月18日 While actual nickelmanganesecobalt oxide (NMC) lithium ion battery (LIB) cathodes are composed of multimetal oxide compounds and solid solutions, the activity ratio of pure metal oxides within single phases of NMC cathodes is far outweighed by their respective P S2 /P SO2 ratios differences This suggests that a sulfidation series Selective Sulfidation and Electrowinning of Nickel and

Manganese and Manganese Alloys Wellbeloved Major

2000年6月15日 Manganese in the Iron and Steel Industry 82 Manganese in Nonferrous Alloys 83 NitrogenContaining Manganese Alloys 9 Processing of Manganese Nodules and Encrustations 91 Occurrence, Origin, and Composition 92 Legal Considerations and Nodule Recovery 93 Processing 931 Gas Reduction and Ammoniacal Leach 2023年7月20日 fairly high, as part ofthe equipment must be made ofstainless steelare taken into account, the overall costs wouldcometo about $650 per ton ofoil The manganese oxide process begins with manganese sulfate (MnSO4), which is treated with sodium hydroxide (NaOH) Further treatment of the sedimentis thesameas thatusedfor The Removal ofSulfur Dioxide Flue Gases2011年1月1日 The processes employed for solution concentration and purification in the hydrometallurgical processing of manganese include precipitation, cementation, solvent extraction and ion exchange Hydrometallurgical Processing of Manganese

A Process for Extraction of Manganese from Manganese Oxide

2023年5月30日 The reduction of manganese oxide ores by biomass was mainly attributed to the thermal degradation productions of biomass, such as liquid, noncondensable gas and solid, among which liquid was the primary reducing agent during the reductive roasting process of manganese oxide ores 37,38 Generally, biomass is not a good microwave To improve the direct alloying of manganese ore in steelmaking, the decomposition and carbon reduction of manganese ore was studied using a differential thermal analyzer and resistance furnace The remaining material after manganese ore decomposition at 1,600 °C was a mixture of 43 % MnO, 40 % MnSiO 3 and FeO, and 17 % MnSiO 3 The Manganese Ore Decomposition and Carbon Reduction in 2023年11月7日 Manganese Dioxide Created by Global Safety Management, Inc Tel: 18134355161 gsmsds CAS Manganese oxide >98 % Percentages are by weight SECTION 4 : First aid measures and processing equipment) are designed in a manner to prevent the escape of dust into the work area (ie, there is no leakage Safety Data Sheet Fisher Sci

Frontiers Application of ManganeseBased Materials in

2020年9月2日 Manganese Oxide Since manganese has a variety of valence states, it could form a series of manganese oxides, such as MnO 2 (Alfaruqi et al, 2016), Mn 3 O 4 (Zhu et al, 2018), etc Due to their special structure, they could be used as cathode materials for AZIBs (Khamsanga et al, 2019; Palaniyandy et al, 2019) Manganese 2023年6月15日 The process flowsheet for the separation and recovery of manganese from braunite via the ammonium sulfate roastingwater leaching process was shown in Fig 2The schematic diagram of the roasting apparatus was shown in Fig S1 a The roasting experiments were performed with samples of braunite size less than 0074 mm 10 g of Highefficiency and environmentfriendly separation and 2 天之前 Henan Fote Heavy Machinery Co, Ltd (FTM Machinery) is a large mining machinery manufacturer and exporter, located in Zhengzhou, Henan, China Our main product categories include stone crusher machine, sand making machine, ore beneficiation plant, powder grinding machine, dryer machine, etc We can provide not only single Fote Machinery Professional Mining Machinery

Manganese Ore Beneficiation Plant Fote Machinery

2023年10月25日 Brazil 200 TPH rock manganese ore beneficiation plant Brazil's manganese ore plant mainly processes the rocktype manganese ore The manganese concentrate is about 46% and contains slime The feed size is 0400 mm and the output is 200 t/h Customer requirements: The product particle size is 2050 mm2023年3月31日 Applying metal catalysts that do not naturally exist requires complex synthetic preprocessing, which thus increases the cost of industrial applications 11, 12 Abundantly available natural mineral catalysts are worth exploring 1315 Natural transition metals and their compounds, such as iron (Fe), cobalt (Co), and manganese (Mn) ores, Natural manganese ores for efficient removal of organic High purity manganese sulphate monohydrate, MSM (MnSO 4 H 2 O) was produced from two types of FeMn smelter wastes (fumes) using a novel process developed incorporating several stages of leaching, roasting, and precipitation Fumes containing high K (as K 2 O) from SIMPAC (Korea) were first leached in water at ambient conditions to render K as Processing of ferromanganese fumes into highpurity manganese

How is manganese extracted? LinkedIn

2022年12月29日 Manganese ore can be extracted using various methods, including physical separation techniques such as gravity separation, magnetic separation and flotation Other methods include chemical 2022年4月28日 Because of the nanoscale tunnel constructed by the active MnO octahedron in cryptomelane, cryptomelanetype manganese oxides have high activity in the oxidation of several volatile organic Manganese Oxide Minerals from the Xiangtan 2023年4月10日 The complete processing flow of manganese ore mainly includes five steps: crushing, washing, grinding, dressing, and drying Next, I will introduce the detailed manganese ore processing production line to you 1 Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves 5 Easy but Efficient Steps to Realize Manganese Ore Processing

The Complete Book on Ferroalloys Semantic Scholar

2017年10月27日 10 PRODUCTION PROCESS OF FERRO SILICON Raw Materials Production of Ferrosilicon, Silicon Metal and Silicocalcium Ferromanganese and Manganese Alloys Refining of Ferrosilicon Introduction Processes for the Refining of Ferrosilicon Solid/Liquid Oxide Method Oxidising Treatment with Gaseous Oxygen/Enriched 2016年4月27日 Concentration—Gravity Methods of treating Manganese Ore The mill feed, drawn from one or more bins, is sampled at the ore feeder discharge to obtain a composite sample for mill control After elevating, a vibrating screen separates the feed into sizes best suited for the Improved Harz Type Jigs and Selective Mineral JigsManganese Ore Processing 911 Metallurgist3 小时之前 • List of Machinery Provider Manganese Oxide, a chemical compound with the formula MnO, stands as a significant player in both industrial and natural processes Manufacturing Process, Plant Manganese Oxide Manufacturing Plant Project Report 2023:

Manganese processing Extraction, Uses Benefits Britannica

manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such as sulfur and oxygen and adds important physical properties to the metal2019年3月11日 At present, the technological process of treating manganese oxide ore in our country usually breaks the ore to 60 mm or 100 mm, then divides the ore into groups, jigs the coarse grade and shaker Beneficiation and Processing Technology of Manganese Ore2019年7月15日 Gravity Separation Process back to top Gravity separation process is a beneficiation method according to the difference in density of minerals, whose process can be carried out in a medium such as water or air The density of common manganese oxide minerals ranges from 3,700 to 5,000 kg/m3, the density of manganese carbonate How to Extract the Manganese Ore? Miningpedia