عنا

مرحبا هل يمكنني مساعدتك؟

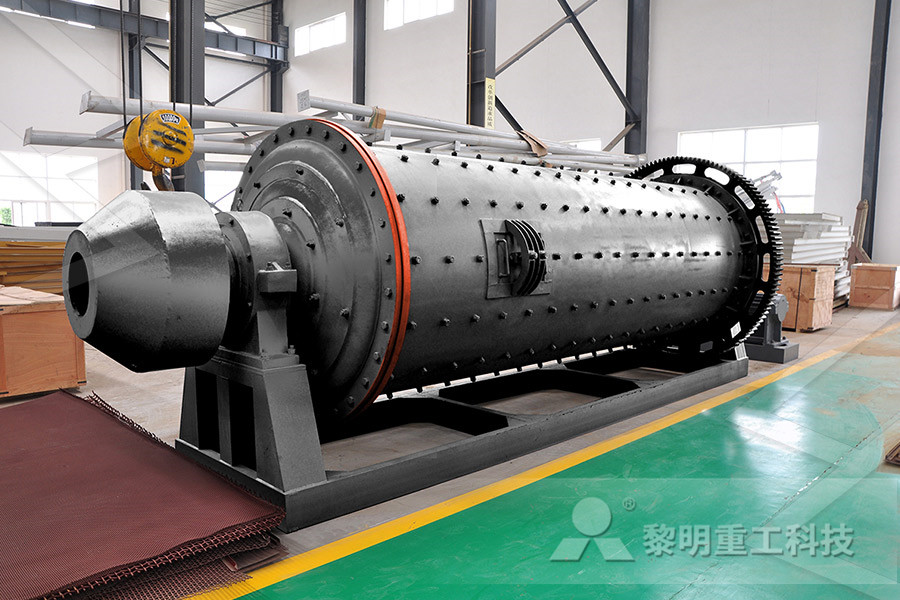

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

equipment for carbonization of coal

2021-07-27T06:07:44+00:00

Activated Carbon Plant Activated Carbon Machine

GBL’s has fullrange equipment for carbonization activation regeneration solution for activated carbon plant, such as the hoist, silo, feeding system, transmission system, carbonization, activation and The Dankuni Coal Complex (WB) carbonizes 1500 ton of noncaking coal per day to produce 100 ton of coke (smokeless domestic coke), 18–20 million ft 3 of gas and 75–80 Coal Carbonization an overview ScienceDirect Topics2022年1月1日 Thus, both types of carbonization equipment and operation parameters should be considered when deciding for the carbonization process The following Biomass carbonization technologies ScienceDirect

Recent advances in hydrothermal carbonisation: from tailored carbon

It was rediscovered back in 2005, on the one hand, to follow the trend set by Bergius of biomass to coal conversion for decentralised energy generation, and on the other hand 1993年1月1日 Coal carbonization involves the destructive distillation of coal, and during this process, as much as 50% of the weight of the coal feedstock is driven off as gaseous 10 Coal Carbonisation ScienceDirect2022年6月1日 In the past 30 years, researchers have developed several methods to synthesize CNTs from coal and coalbased derivatives, eg, the arc discharge, laser Synthesis, modification strategies and applications of coal

Modeling the Coal Tar Pitch Primary

2022年11月26日 2 Materials and Methods Coal tar pitch (CTP) is a complex mixture of polycyclic aromatic hydrocarbon (PAH) and heterocyclic compounds, which composition will be evolving during carbonization 2021年6月7日 bonization equipment generally uses either a metal box or wooden box as packing and shifting the coal inside the hot furnaces for carbonization The biggest LaboratoryScale Integrated Coke Dry Quenching 2013年2月5日 Carbonization, more narrowly defined, refers to conversion of a starting material into carbon, or a carbonrich solid It is entirely possible, and indeed often done, Carbonization and coking of coal (Chapter 23) Chemistry of

Emerging CO2Mineralization Technologies for Co

2021年3月7日 CO2 mineralization (aka mineral carbonation) is a promising method for the chemical sequestration of CO2 via reaction with oxides of alkaline or alkalineearth metals to form carbonates It has documented @article{osti, title = {Coal carbonization: current and future applications}, author = {Menendez, R and Alvarez, R}, abstractNote = {Carbonization is defined as the destructive distillation of organic substances in the absence of air, accompanied by the production of carbon and liquid and gaseous products The coke produced by carbonization of coal is Coal carbonization: current and future applications OSTIGOV2021年2月5日 Carbonization test using pilot coke oven is an important laboratoryscale analysis to evaluate cokemaking ability of metallurgical coals RDCIS, SAIL, comprises a pilot oven of 250 kg coal charging capacity, with the facility of both top and stamp chargings The functional pilot coke oven of this size for carbonization test is expensive and requires LaboratoryScale Integrated Coke Dry Quenching System for Coal

Metals Free FullText Influence of BioCoal

2021年10月31日 A TGA equipment Netzsch STA 409, with graphite furnace , was used when studying the reactivity of the coke and biocoke Carbonization was done using TGA/QMS equipment The TGA results 2023年10月19日 Coal is a black or brownishblack sedimentary rock that can be burned for fuel and used to generate electricity It is composed mostly of carbon and hydrocarbons, which contain energy that can be released through combustion (burning) Coal is the largest source of energy for generating electricity in the world, and the most abundant fossil fuel Coal National Geographic Society2022年1月1日 The aim of this research was to evaluate the technoeconomic prospect of hydrochar production through cohydrothermal carbonization of coal waste (CW) and food waste (FW) A process flow diagram Technoeconomic analysis of cohydrothermal carbonization of coal

Influence of coal properties on coal conversion processescoal

2021年2月8日 The chemical constituents present in coal structure impact greatly on its mechanical behavior The composition of organic matter and its degree of decomposition led to varying coal strength and modulus of elasticity of different coals (Pan et al 2013; Singh and Mrityunjay 2018b; Ahamed et al 2019) as the chemical structure was alteredCoals 2023年7月1日 To improve the utilization value of coal resources and optimize the production process of coalbased activated carbon, an L 9 (3 4) orthogonal experiment was designed to study the comprehensive effects of the carbonization temperature, heating rate, activation time and activator type on the specific surface area and iodine value of Preparation and performance of coalbased activated carbon 2023年6月10日 Download reference work entry PDF Semi coke is the solid products, obtained from lowrank bituminous coal, lignite, or peat by carbonization at low temperature (500–750 °C) in a retort furnace In general, semi coke is also a byproduct or intermediate product of the conversion of coal into liquid and gaseous fuels (Fig 1 )Semi Coke SpringerLink

Technoeconomic analysis of cohydrothermal

carbonization of coal waste (CW) and food waste (FW) A process flow diagram was developed that considered seven reactors, six pumps, and other necessary equipment for producing 49,192 kg/h hydrochar Three different cases were considered for the economic analysis Case II considered both CW and FW transportation cost while cases I and III 2018年12月8日 Coal carbonization is the process by which coal is heated and volatile products (liquid and gaseous) are driven off, leaving a solid residue called coke Carbonization of coal involves heating coal to high Coal Carbonization for Coke Production – IspatGurucarbonization In chemical industry: Benzene from the carbonization (heating) of coal, which produces coke, combustible gas, and a number of byproducts, including benzene Carbonization of coal to produce Coal processing Britannica

Modeling the Coal Tar Pitch Primary

2022年11月26日 The properties of the carbon materials obtained as the final product of coal tar pitch carbonization process are a consequence of the type of chemical and physical phenomena occurring through the 2020年3月10日 Coal plasticity is a phenomenon directly affecting the creation of coke structure It is very much a time and temperaturedependent transformation of the coal matrix, which allows changing the physical phase from solid to liquidlike and again into solid of different properties The coking process, particularly in a plasticization temperature Kinetic modelling of coking coal fluidity developmentAbstract Carbonisation is the term used to denote the heating of coal in the absence of air In these circumstances, volatile matter (VM) is removed The volatiles are higher in hydrogen content than the basic coal, which therefore increases in carbon — hence, “carbonization” As noted elsewhere, the offgases can be useful; fuel gases The Carbonisation of Coal SpringerLink

TechnoEconomic Assessment of CoHydrothermal Carbonization of a Coal

2019年2月15日 Saba et al 95 presented a technoeconomic assessment (TEA) on the use of miscanthus HC and a coal blend They reported an estimated cost around 108 M€ for a HTC plant of 43 t HC/h capacity About GreenPower GreenPower is an international BioEnergy company, which specializes in the development and production of equipment specialized processes of “pyrolysis”, “gasification”, “activation of charcoal” The main specialization of GreenPower company is developing and manufacturing the carbonization furnaces, the different GreenPower ️ CompanyWhat is carbonization? Carbonization definition Activated carbon is a specially treated carbon that heats organic raw materials (nut shells, coal, wood, etc) in the absence of air to reduce noncarbon components (this process is called carbonization process), and then reacts with the gas, to let its surface be corroded and produce microporous structure (this Carbonization Machine, Carbonization Process of Activated

Coal Activated Carbon Production Process Best Activated

Commonly used equipment mainly includes activated carbon rotary kilns, fluidized furnaces, and vertical carbonization furnaces Coalbased activated carbon plant Coal activated carbon is usually carbonized at a temperature of 350600 °C In the carbonization process, most of the noncarbon elements – hydrogen and oxygen are firstly 1 A coal gasification process by a grading conversion of carbon hydrogen components of the coal, comprising the steps of: a carbonization process, a monoxideproducing process and a shift reaction process, wherein the carbonization process carbonizes the gasifying coal to produce a product comprising crude coke, cokeoven gas and tar; the carbon PROCESS AND EQUIPMENT FOR COAL GASIFICATION, AND POWER GENERATION 2013年2月5日 All coals, regardless of whether they are caking or coking coals, leave a solid carbonaceous residue at the end of the carbonization process Chars, if heattreated to extreme temperatures, eg ≥2500 °C, do not form graphite, while cokes do That is, chars are nongraphitizable, while cokes are graphitizable [A] TypeCarbonization and coking of coal (Chapter 23) Chemistry of

Carbonization unit BIOFURNACE ️ GreenPower

The carbonization furnace BIOKILN is a patented, environmentally friendly, continuous installation for the thermal processing of plants materials It is designed specifically for the production of highquality charcoal or 1993年1月1日 This chapter discusses coal carbonization Coal carbonization involves the destructive distillation of coal, and during this process, as much as 50% of the weight of the coal feedstock is driven off as gaseous and volatile components These are regarded as byproducts of the coking process, and include combustible gases (for example, methane 10 Coal Carbonisation ScienceDirect2020年3月20日 The coal supply chain network is described as follows: the supply chain network is a fourlevel network structure, including coal mines, coal washery, coal distribution centers and power plants (Fig 1) (Ding et al, 2018), in which the available reserves of coal mines and the generation demand of power plants are known, Sustainable design and optimization of coal supply

A MiniReview: BiowasteDerived Fuel Pellet by

2022年10月1日 This review article focuses on recent studies using hydrothermal carbonization (HTC) for producing hydrochar and its potential application as a solid fuel pellet Due to the depletion of fossil fuels and increasing greenhouse gas (GHG) emissions, the need for carbonneutral fuel sources has increased Another environmental concern 2022年9月12日 In this study, we studied the feasibility of preparing highquality needle coke from coal liquefaction pitch Nine types of blending pitch (coal liquefaction pitch and anthracene oil mixed with different ratios) were used as raw materials to generate needle coke via the cocarbonization method Optical microscopy, Xray diffraction, Raman Generation and characterization of coalbased needle coke 2021年2月17日 The oxygen of the air is used up in burning part of the wood charged The spontaneous breakdown or carbonization of the wood above a temperature of 280°C liberates energy and hence this reaction is said to be exothermic This process of spontaneous breakdown or carbonization continues until only the carbonised residue Chapter 4 Carbonisation processes Food and Agriculture

Hypercoal对不同炼焦煤炭化改质作用的显微镜研究

2012年3月30日 Seongho, MOCHIDA I Modification performance of Hypercoal as an additive on cocarbonization of coal[J] Journal of Fuel Chemistry and Technology, 2012, 40(09): 10251031 PDF下载 ( 6972 KB) Hypercoal对不同炼焦煤炭化改质作用的显微镜研究 Different coals were used as raw material for the preparation of carbonization precursors and coalbased activated carbons The physicochemical structure and adsorption performance of the samples were tested Results show that the carbonization and activation process greatly changed the molecular structure of raw coal, and a large number of OneStep Preparation of Activated Carbon for Coal Bed 2021年10月13日 Coal remains the backbone of the iron and steel industry and cement subsectors, and its use in the chemical subsector keeps increasing, particularly in China In the Sustainable Development Scenario, industrial coal consumption is estimated to be 844 Mton Hydrochar can provide a great opportunity to replace fossil coal as it offersHydorthermal Carbonization (HTC): Valorisation of

Carbonization of Coal UNESCO

2017年1月16日 Cokemaking equipment from coals has developed from the beehive oven to the jumbo coking reactor Modern coke ovens are mainly composed of carbonization chambers, Carbonization of coal, thermal decomposition of coals in the absence of air, represents one of the largest utilizations of coal, and is an essential process for 2022年12月15日 including duration, temperature, and pressure The results reveals that the carbonization process of MSW is very much effective to reduce the CO2 emission and global warming 1 Introduction The hydrothermal carbonization (HTC) process converts biomass to coal in 12 hours by a chemical reaction that transforms natural wastes into GURWKHUPDODUERQLVDWLRQ3ODQW 2021年6月1日 Activated cokes have been prepared with a twostep process: cocarbonization of bituminous coal and poplar bark biomass in nitrogen at moderate temperatures, followed by physical activation of the char residues with CO 2 and steam at higher temperatures The microstructures, pore distributions and surface chemical Activated coke preparation by physical activation of coal and

Hydrothermal carbonization of biomass: experimental study,

2022年2月28日 The average of these two points was 5429 as reported in Table S4 Avocado pits have previously been used as an HTC feedstock, and the average liquid yield was reported to be 5411% for a reaction rank coal by hydrothermal carbonization for efficient iodine removal Yufeng Yin,a Dingcheng Liang, *a Deqian Liua and Qianjun Liub Lowrank coal, such as Shengli lignite (SL) and Datong bitumite (DT), has abundant reserves and is low in cost Due to its high moisture content, abundant oxygencontaining groups, high ash content and lowPreparation and characterization of threedimensional 2020年4月1日 Coal tar and pitch have been used as a binder in a carbonization blend to improve coalcaking property and ultimately the strength of the produced coke (Chatterjee and Prasad 1983;GonzalezCimas Carbonization Characteristics of Biomass/Coking Coal Blends

Mechanism of the evolution of pore structure during the

carbonization process using a coal sample; then, the evolution of the pore structure of AC under different conditions was examined by smallangle Xray scattering (SAXS) and the N results in slagging and corrosion of the production equipment aSchool of Chemical and Environmental Engineering, China University of Mining and Technology 2021年7月1日 However, the cocarbonization of coal tar pitch and bioasphalt to prepare spinnable pitch for carbon fiber has not been studied so far Cocarbonization of biotar with ethylene bottom oil [26] was found to be effective to form high softening point pitch Besides, the abundance of aliphatic structures introduced by biotar could improve the Preparation of isotropic spinnable pitch with highspinnability It was rediscovered back in 2005, on the one hand, to follow the trend set by Bergius of biomass to coal conversion for decentralised energy generation, and on the other hand as a novel green method to prepare advanced carbon materials and chemicals from biomass in water, at mild temperature, for energy storage and conversion and environmental Recent advances in hydrothermal carbonisation: from tailored carbon

Lurgi Process an overview ScienceDirect Topics

Hydrocarbons from Coal James G Speight PhD, DSc, in Handbook of Industrial Hydrocarbon Processes, 2011 6411 The Lurgi process The Lurgi process was developed in Germany before World War II and is a process that is adequately suited for largescale commercial production of synthetic natural (Verma, 1978) The older Lurgi process is a @article{osti, title = {Coal carbonization: current and future applications}, author = {Menendez, R and Alvarez, R}, abstractNote = {Carbonization is defined as the destructive distillation of organic substances in the absence of air, accompanied by the production of carbon and liquid and gaseous products The coke produced by carbonization of coal is Coal carbonization: current and future applications OSTIGOV2021年2月5日 Carbonization test using pilot coke oven is an important laboratoryscale analysis to evaluate cokemaking ability of metallurgical coals RDCIS, SAIL, comprises a pilot oven of 250 kg coal charging capacity, with the facility of both top and stamp chargings The functional pilot coke oven of this size for carbonization test is expensive and requires LaboratoryScale Integrated Coke Dry Quenching System for Coal

Metals Free FullText Influence of BioCoal

2021年10月31日 A TGA equipment Netzsch STA 409, with graphite furnace , was used when studying the reactivity of the coke and biocoke Carbonization was done using TGA/QMS equipment The TGA results 2023年10月19日 Coal is a black or brownishblack sedimentary rock that can be burned for fuel and used to generate electricity It is composed mostly of carbon and hydrocarbons, which contain energy that can be released through combustion (burning) Coal is the largest source of energy for generating electricity in the world, and the most abundant fossil fuel Coal National Geographic Society2022年1月1日 The aim of this research was to evaluate the technoeconomic prospect of hydrochar production through cohydrothermal carbonization of coal waste (CW) and food waste (FW) A process flow diagram Technoeconomic analysis of cohydrothermal carbonization of coal

Influence of coal properties on coal conversion processescoal

2021年2月8日 The chemical constituents present in coal structure impact greatly on its mechanical behavior The composition of organic matter and its degree of decomposition led to varying coal strength and modulus of elasticity of different coals (Pan et al 2013; Singh and Mrityunjay 2018b; Ahamed et al 2019) as the chemical structure was alteredCoals 2023年7月1日 To improve the utilization value of coal resources and optimize the production process of coalbased activated carbon, an L 9 (3 4) orthogonal experiment was designed to study the comprehensive effects of the carbonization temperature, heating rate, activation time and activator type on the specific surface area and iodine value of Preparation and performance of coalbased activated carbon 2023年6月10日 Download reference work entry PDF Semi coke is the solid products, obtained from lowrank bituminous coal, lignite, or peat by carbonization at low temperature (500–750 °C) in a retort furnace In general, semi coke is also a byproduct or intermediate product of the conversion of coal into liquid and gaseous fuels (Fig 1 )Semi Coke SpringerLink

Technoeconomic analysis of cohydrothermal

carbonization of coal waste (CW) and food waste (FW) A process flow diagram was developed that considered seven reactors, six pumps, and other necessary equipment for producing 49,192 kg/h hydrochar Three different cases were considered for the economic analysis Case II considered both CW and FW transportation cost while cases I and III