عنا

مرحبا هل يمكنني مساعدتك؟

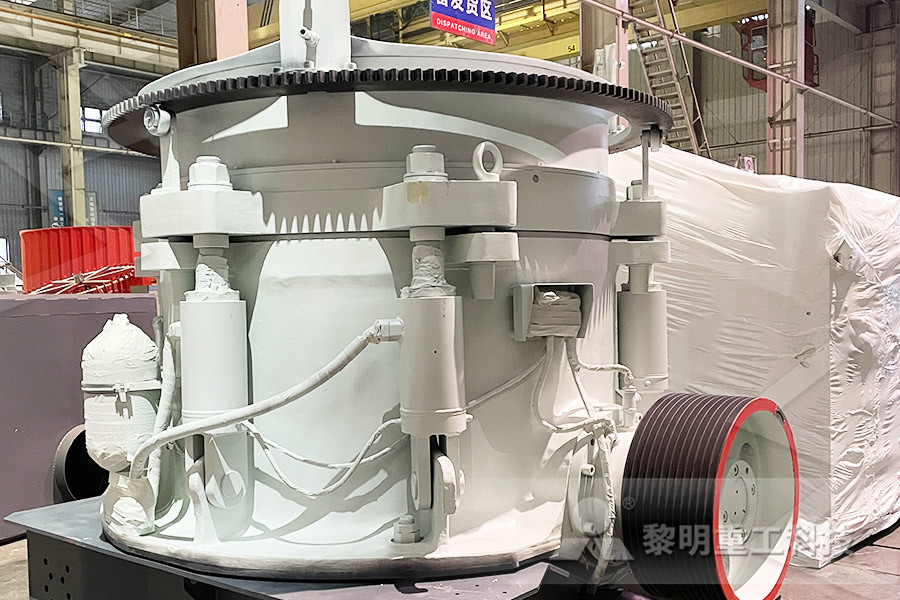

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Gold Ores Flotation Separators

2023-10-22T21:10:24+00:00

Review articleA systematic review of sustainable gold

2022年3月1日 Gold flotation is widely used in the case of refractory ores, in which smallsized gold particles, locked within sulfide minerals, are recovered through flotation of gold 2021年9月24日 Based on the analysis of the literature [ 11, 12, 13, 14 ], it has been established that the most demanded direction is the processing of goldbearing ores with Integrated Technology for Processing GoldBearing Ore2012年1月25日 flotation Gold concentration usually consists of gravity separation, flotation, cyanidation, or the combination of these processes The choice among these Beneficiation of the gold bearing ore by gravity and flotation

Beneficiation of the gold bearing ore by gravity and

2017年8月27日 In this study, gold preconcentrates were pro duced by the stepwise gravity separation and flotation techniques The Knelson concentrator and conventional 2019年2月13日 The flotation method is a technique widely used for the recovery of gold from gold containing copper ores, base metal ores, copper nickel ores, platinum group 17 Flotation of Gold Ores Aalto2021年12月17日 The flotation products from each configuration were evaluated in terms of overall Cº ma4er recovery and combined concentrate grade Figure 1 The flotation The Separation of Carbonaceous Matter from Refractory

Study of the Technology for Gold Recovery from GravityFlotation

2022年6月13日 The majority of gold processing plants currently handle ores containing sulfide minerals Gold in such ores is partially associated with sulfides and partially in a 2005年1月1日 In Brazil, the application of flotation for goldbearing ores started in the 1980s (Araujo and Peres, 1995) There are three important Brazilian plants using Flotation of gold and goldbearing ores ScienceDirect2017年8月28日 flotation for gold from its tailings [79] Thereafter, both of the two concentrates were processed by roastingcyanidation method In this way, gold was GOLD EXTRACTION FROM A HIGH CARBON LOW

Titanium Ore Processing and Beneficiation 911

2016年5月9日 The nonmagnetic fraction is subjected to high intensity electrostatic separation which removes the high grade rutile—9495% TiO2 Rejects are treated by flotation to recover the zirconium Possibilities For 2023年6月7日 Mineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals (usually called gangue) or hazardous minerals, or to separate multiple useful minerals In the early years, mineral processing was called mineral concentration or mineral engineering in ChinaMineral Processing SpringerLink2016年1月1日 Flotation Certain gold ores, mainly those containing sulfides, arsenides, or tellurides, are best treated by producing a flotation concentrate (Anderson, 1980, Jones and Woodcock, 1984, King, 1982) This is almost always the case in treating refractory gold ores, where the refractory nature of the ore is due to sulfide mineral speciesMetallurgical Test Work: Gold Processing Options, Physical

Metals Free FullText Correlation between Flotation and

2022年2月1日 Otsuki and Yue (2017) [ 36] Adoption of CGAassisted flotation to a complex gold ore Higher gold recovery (9433%) and grade (7542 g/t) was achieved with the CGA process as compared with the recovery (9244%) and grade (3663 g/t) in flotation without CGA, especially in the fine particle fraction (between 38–53 µm)2008年2月1日 The results of gravity tests have indicated that 81% of the gold from the ground ore (74 μm) can be recovered into a concentrate (Con1) with a grade of 262 g/t Au at a 72% yield A clean (PDF) Recovery of gold from a freemilling ore by2022年6月21日 In the case of gold and PGE, gravity separation can quickly generate a precious metal concentrate that can be sold direct to refineries, resulting in better payment terms, faster payback and immediate cashflows The small footprint of these gravity plants means less capital outlay and better security for these small, volume highvalue Gravity Separation SGS

CHAPTER7 GRAVITY CONCENTRATION OF IRON ORE

2020年5月6日 MGS has been applied successfully for gold, zinc, tantalum, tin, copper and lead While the performance of the MGS was found to be superior compared to other fines gravity separators for reduction of alumina in iron ores, the low capacity is the major limitation in the application of MGS for the treatment of the iron ore slimesThe amount of nonvaluable gangue minerals could be more than 990 % for gold or PGM ores, ~97 % for a copper ore containing 1 % Cu as chalcopyrite and froth separators Of these, mechanical flotation machines have dominated the mineral industries since the early days of froth flotation all over the world 81 Mechanical Flotation CellsPhysical Processing: Innovations in Mineral Processing2023年5月27日 Gold Flotation Equipment Flotation Cell Yes, I am interested! Gold ores finer than 10 μm are difficult to recover by gravity separation Froth flotation utilizes the hydrophobicity of gold to separate it from gangue, thereby recovering finegrained and ultrafinegrained gold particles8 Pieces of Gold Mining Equipment to Get Gold Concentrates

A systematic review of sustainable gold extraction from raw ores

2022年3月1日 Sluices are primaeval gravity separators The slurry is introduced at the top of the channel: turbulence induced by water flow vibrates the bed and promotes its fluidisation and stratification according to the density and size of the particles Optimisation of gold recovery by selective gold flotation for coppergoldpyrite ores 2020年6月15日 Most research on the separation mechanism of a KC has been conducted with MD3 concentrators and synthetic ores KCMD3 with a 3in (75 cm) concentrating cone is suitable for laboratory research because it is portable and convenient, and the amount of raw material is adjustable (Banisi, 1992, Putz, 1994)Synthetic ores composed Research and application of a Knelson concentrator: A review2016年1月1日 1 Background The application of flotation on a reasonable scale within the goldmining industry commenced in the early 1930s following the introduction of watersoluble flotation collectors (specifically xanthates and dithiophosphate collectors) that allowed differential flotation of sulfide minerals (Weinig and Carpenter, 1937, Rabone, Flotation of Gold and GoldBearing Ores ScienceDirect

Minerals Free FullText Specific Refractory Gold

2021年1月19日 This paper presents a research overview, reconciling key and useful case study findings, towards uncovering major causes of gold refractoriness and maximising extraction performance of specific gold 2023年4月22日 The flotation performance of goldcopper ores can be affected by various factors, such as mineralogy, particle size distribution, reagent dosage, pulp density, pH, Eh, etc These factors can Mixed Copper and Gold Ore Concentrates Processing2001年2月1日 The gold contained in copper ores is an important resource for the gold industry In some cases, elemental gold is present and can be recovered by selective flotationOptimisation of gold recovery by selective gold flotation for copper

(PDF) Physical separation methods, Part 1: A Review

2019年11月19日 The gold grades in the ores and artisanal gold mine tailings were in the ranges of 37–152 and 2–7 g t−1, respectively Quartz was a major phase, with minor impurities in two different types 2023年11月1日 Nickel ores mainly include coppernickel sulfide ore and nickel oxide ore (laterite nickel ore) The most important is the nickel ore flotation process, magnetic separation and gravity separation are usually auxiliary beneficiation methods We can customize nickel ore beneficiation process and equipment to achieve comprehensive Nickel Ore Beneficiation Plant Mineral Processing2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic Iron Ore Processing, General SpringerLink

A systematic review of sustainable gold extraction from raw ores

2022年3月1日 Environmentally friendly ligands, alternatives to cyanide, are desired to extract gold for the sustainable hydrometallurgy of gold Leaching characteristics of gold were examined using thiourea (TU) and ethylene thiourea (ETU) as ligands from three types of gold ores with different Fe contents from 270 to 1409 wt% under the acidic condition2021年11月1日 As a pretreatment method of refractory gold ore, carbonaceous matter (Cmatter) flotation was investigated with multistage flotation by rougher, scavenger, and cleaner stages Different dosages of kerosene and MIBC (4Methyl2pentanol) were applied and the optimum dosage was selected by testing in each flotation stage With the The Separation of Carbonaceous Matter from Refractory Gold 2020年2月14日 The gold grades in the ores and artisanal gold mine tailings were in the ranges of 37–152 and 2–7 g t−1, respectively Quartz was a major phase, with minor impurities in two different types (PDF) Editorial for the Special Issue: “Physical ResearchGate

Spiral Separators Mineral Processing

2023年11月6日 It is widely used in the treatment of tungsten, tin, gold, platinum, iron and some rare metal ores, especially in the treatment of lowgrade sand ores Large processing capacity, high work efficiency, low cost and energy saving The spiral separator has stable performance, clear ore separation, high enrichment ratio and recovery rateIn 1997 Newmont USA Ltd introduced the N2TEC process for the flotation recovery of auriferous pyrite and other sulfide minerals in Carlin type ores, using nitrogen as the flotation gas, and low Jan MILLER Ivor D Thomas Distinguished Professor PhD 2019年7月1日 The technological mineralogy of a gold deposit located in NorthWestern province of Zambia was carried out by using Xray fluorescence spectroscopy (XRF), Xray diffraction spectroscopy (XRD), and scanning electron microscope (SEM) The results showed that gold was highly dispersed in goldbearing minerals such as pyrite, Mineralogy and Pretreatment of a Refractory Gold Deposit in

Minerals Free FullText SimulationBased Analysis of

2021年5月19日 In this work, two hydrometallurgical processes for gold recovery are explored for a smallscale gold mining case study located at Ponce Enriquez, Azuay, Ecuador The hydrometallurgical systems consider the use of sodium cyanide and sodium thiosulfate as leaching agents, with and without the incorporation of a subsystem for Flotation makes possible the processing of complex intergrown ores containing copper, lead, zinc, and pyrite into separate concentrates and tailings—an impossible task with gravity, magnetic, or electric separation methods In the past, these metals were recoverable only with expensive metallurgical processes Magnetic separationMineral processing Concentration, Separation, FlotationFigure 13 shows metal recovery resulted from simulation and Figure 8 shows metal recovery without flash flotation installed Without flash flotation installed gold recovery is 7327% while with flotation installed, predicted gold recovery is 7802% So installation of flash flotation will improve metal recovery about 475% for goldImprovement of Gold Recovery at North and South

E3S of Conferences 168, 00005 (2020) RMGET 2020

Gold flotation is used for refractory goldbearing ores and products containing 13 g/t of gold During flotation processing of polymetallic ores, gold is simultaneously recovered in appropriate concentrates (copper, zinc, etc) The extraction of gold into copper and zinc concentrates is from 30 to 35 %, the remaining gold goes into2022年6月13日 The majority of gold processing plants currently handle ores containing sulfide minerals Gold in such ores is partially associated with sulfides and partially in a free state Ores of this type are in most cases classified as refractory The raw material for gold recovery is the gravityflotation concentrate of ore enrichmentStudy of the Technology for Gold Recovery from GravityFlotation The coarser fractions in flotation feeds contain heavy and valuable liberated and non liberated minerals that cannot be floated efficiently There is a top limit for particle size floatability which varies for different ores The specific gravity of these particles plays an important role which causes decreasing the flotation performanceScavenging flotation tailings using a continuous centrifugal

Diagnosis and Optimization of Gold Ore Flotation

2021年9月29日 The aim of this study is to diagnose and optimize a closed multistage gold ore flotation circuit in an operational industrial plant Linear circuit analysis (LCA), a partitionbased model, and a mass balance 2014年4月16日 FROTH FLOTATION: Flotation process can be categorized as: 1) PLAIN FLOTATION: it was 1st practised in MP to obtain one type of concentrate from sulfide ore 2) BULK FLOATATION Mineral processing ii PPT SlideShareYou can not select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters long/ mineral air seperators for goldmd at master

A Review of the Cyanidation Treatment of CopperGold Ores

2020年5月21日 Globally, copper, silver, and gold orebody grades have been dropping, and the mineralogy surrounding them has become more diversified and complex The cyanidation process for gold production has remained dominant for over 130 years because of its selectivity and feasibility in the mining industry For this reason, the industry has 2021年11月1日 As a pretreatment method of refractory gold ore, carbonaceous matter (Cmatter) flotation was investigated with multistage flotation by rougher, scavenger, and cleaner stages Different dosages of kerosene and MIBC (4Methyl2pentanol) were applied and the optimum dosage was selected by testing in each flotation stage With the The Separation of Carbonaceous Matter from Refractory Gold Ore 2020年5月6日 A wide range of gravity separators are available for concentration of various types of ores with feed of varying particle size distribution Ageneral classification of the various types of gravity separators with their specific applications are given in Table 112nI, while the operating particle size range of the common separators isconcentrator and MGS are discussed Motley Vanner,

Characterization of Flotation and Leaching in Cyanide and

2023年2月12日 Highgrade gold ores are generally associated with iron, copper, and silver sulfides, among other species that during dissolution consume the leaching agent, causing a decrease in the leaching rate In this work, the flotation, and the comparison of the leaching with cyanide and thiourea (TU) of an ore rich in Au, Ag, and Cu were studied2022年5月12日 This study presents the novel idea of a cyanidefree leaching method, ie, glycineammonia leaching in the presence of permanganate, to treat a lowgrade and copperbearing gold tailing Ammonia played a key role as a pH modifier, lixiviant and potential catalyst (as cupric ammine) in this study Replacing ammonia with other pH Extraction of Gold and Copper from Flotation Tailings Using 2012年1月25日 Gold concentration usually consists of gravity separation, flotation, cyanidation, or the combination of these processes The choice among these processes depends on the mineralogical characterization and gold content of the ore Recently, the recovery of gold using gravity methods has gained attention because of low cost and Beneficiation of the gold bearing ore by gravity and flotation

(PDF) Gravity separation by falcon concentrator an over

2022年1月20日 Falcon concentrators as enhanced gravity separators have been developed for the sharper separation beneficiation of finely disseminated ores based on their specific gravity differences Falcon 2016年5月9日 The nonmagnetic fraction is subjected to high intensity electrostatic separation which removes the high grade rutile—9495% TiO2 Rejects are treated by flotation to recover the zirconium Possibilities For Titanium Ore Processing and Beneficiation 911 2023年6月7日 Mineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals (usually called gangue) or hazardous minerals, or to separate multiple useful minerals In the early years, mineral processing was called mineral concentration or mineral engineering in ChinaMineral Processing SpringerLink

Metallurgical Test Work: Gold Processing Options, Physical

2016年1月1日 Flotation Certain gold ores, mainly those containing sulfides, arsenides, or tellurides, are best treated by producing a flotation concentrate (Anderson, 1980, Jones and Woodcock, 1984, King, 1982) This is almost always the case in treating refractory gold ores, where the refractory nature of the ore is due to sulfide mineral species2022年2月1日 Otsuki and Yue (2017) [ 36] Adoption of CGAassisted flotation to a complex gold ore Higher gold recovery (9433%) and grade (7542 g/t) was achieved with the CGA process as compared with the recovery (9244%) and grade (3663 g/t) in flotation without CGA, especially in the fine particle fraction (between 38–53 µm)Metals Free FullText Correlation between Flotation and 2008年2月1日 The results of gravity tests have indicated that 81% of the gold from the ground ore (74 μm) can be recovered into a concentrate (Con1) with a grade of 262 g/t Au at a 72% yield A clean (PDF) Recovery of gold from a freemilling ore by

Gravity Separation SGS

2022年6月21日 In the case of gold and PGE, gravity separation can quickly generate a precious metal concentrate that can be sold direct to refineries, resulting in better payment terms, faster payback and immediate cashflows The small footprint of these gravity plants means less capital outlay and better security for these small, volume highvalue 2020年5月6日 MGS has been applied successfully for gold, zinc, tantalum, tin, copper and lead While the performance of the MGS was found to be superior compared to other fines gravity separators for reduction of alumina in iron ores, the low capacity is the major limitation in the application of MGS for the treatment of the iron ore slimesCHAPTER7 GRAVITY CONCENTRATION OF IRON OREThe amount of nonvaluable gangue minerals could be more than 990 % for gold or PGM ores, ~97 % for a copper ore containing 1 % Cu as chalcopyrite and froth separators Of these, mechanical flotation machines have dominated the mineral industries since the early days of froth flotation all over the world 81 Mechanical Flotation CellsPhysical Processing: Innovations in Mineral Processing

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023年5月27日 Gold Flotation Equipment Flotation Cell Yes, I am interested! Gold ores finer than 10 μm are difficult to recover by gravity separation Froth flotation utilizes the hydrophobicity of gold to separate it from gangue, thereby recovering finegrained and ultrafinegrained gold particles2022年3月1日 Sluices are primaeval gravity separators The slurry is introduced at the top of the channel: turbulence induced by water flow vibrates the bed and promotes its fluidisation and stratification according to the density and size of the particles Optimisation of gold recovery by selective gold flotation for coppergoldpyrite ores A systematic review of sustainable gold extraction from raw ores