عنا

مرحبا هل يمكنني مساعدتك؟

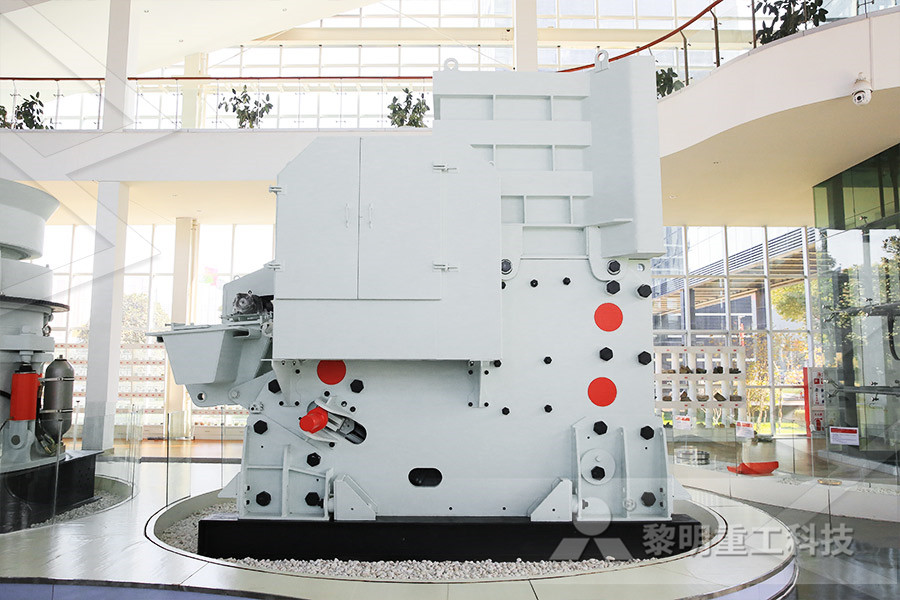

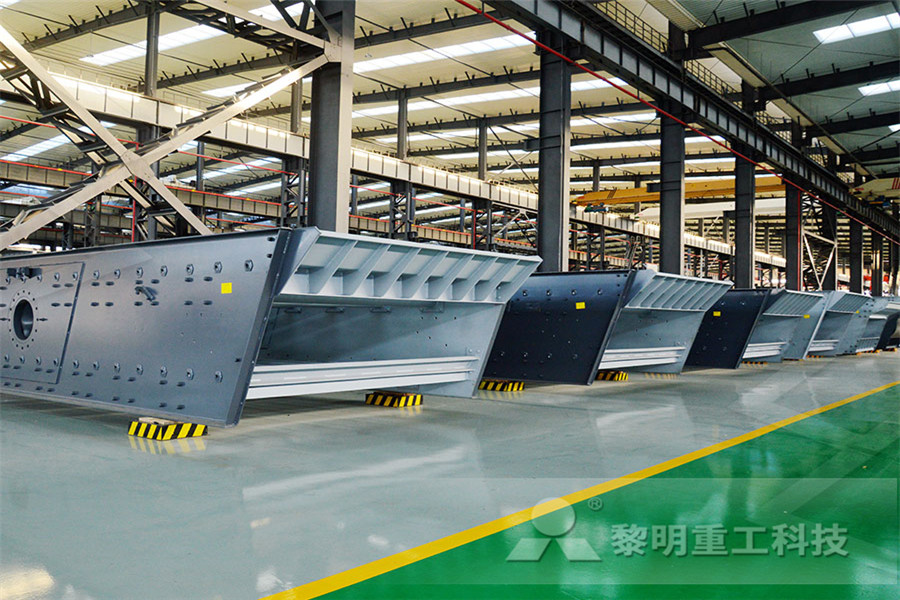

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

industrial wet ball mill bemer

2023-05-07T10:05:55+00:00

Vibration Feature Extraction and Analysis of Industrial Ball

2015年1月1日 Abstract The use of advanced technologies such as Microelectromechanical system (MEMS) sensors and low power wireless communication hold 2020年9月1日 Wet ball milling is a green and laborsaving technology at room temperature Wet ball milling of biochar with organic solvents (such as ethanol, hexane, and heptane) Ball milling as a mechanochemical technology for2020年12月1日 Online monitoring load parameters inside the ball mill is the key to improving the production quality and quantity of the mineral grinding process In this Experimental analysis of wet mill load parameter based on

Ballimpact energy analysis of wet tumbling mill using a

2020年11月1日 The numerical analysis of the ballimpact energy showed that relatively highimpact energy of balls was intensively generated near the vessel wall, indicating 2019年1月21日 Wet process ball mill Feeding size:≤25mm Motor Power:185800kw Wet process ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, Wet process ball millBAILING® Machinery2021年2月5日 Investigation on measuring the fill level of an industrial ball mill based on the vibration characteristics of the mill shell Mater Eng 2009; 14: 1200–1208 Google Integrated approach for ball mill load forecasting based on

Wet ball milling of niobium by using ethanol, determination

2021年11月17日 Abstract This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb) Dried nanocrystal Nb powders, 1 / 6 Mining Ore Lead Manganese Iron Slag Sliver Aluminum Zinc Cement Powder Grinding Wet Gold Copper Ball Mill US$ 500030000 / Set 1 Set (MOQ) Type : Ball Mill Motor China Wet Ball Mills, Wet Ball Mills Manufacturers, Suppliers, Find your wet mill easily amongst the 32 products from the leading brands (Retsch, Fritsch GmbH, , ) on DirectIndustry, the industry specialist for your professional Wet mill, Wet grinding system All industrial manufacturers

球磨机百度百科

2023年8月15日 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿 2023年9月1日 1 Mineral Processing: Wet ball mills are extensively used in the mineral processing industry to grind ores and minerals for further processing They are employed in various stages of What is a wet overflow ball mill and its applications LinkedIn2022年8月11日 This study investigated the effect of grinding media on the finegrinding performance in the wet tumbling mill Comparative experiments between cylpebs and ceramic balls were conducted in a laboratory wet ball mill under various conditions, such as different total masses, total surface areas, and total numbers The results indicated that Minerals Free FullText A Comparison of the FineGrinding

Ball Mills 48 Manufacturers, Traders Suppliers

2023年10月14日 Ball MillsCPB offers state of the art ball mills:with slide shoe bearing to reduce stress in the mill shell and mill internalswith lateral gear drive and self aligning pinionwith a central lubrication systemwith large reinforced manholes (540 x 640 mm) for optimal maintenance and assembly conditionspossible installed engine performance: 2021年11月17日 This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb) Dried nanocrystal Nb powders, of high purity, with particle sizes Wet ball milling of niobium by using ethanol, determination 2021年9月5日 Several mathematical models have been developed to predict the PSDs of particulate materials, including lognormal, logistic, Gates–Gaudin–Schuhmann (GGS), and Rosin–Rammler (RR) distributions, while truncated size distributions can also be used when a particle population would have every particle smaller than a definite top size [38, 39]In Modeling of Bauxite Ore Wet Milling for the Improvement of

Ball Mill Manufacturer Neumann Machinery Company

Founded in 1984 with the acquisition of the EIMCO ball, pebble and rod mill product lines Neumann Machinery Company (NMC) is headquartered in West Jordan, Utah, in the USA just 14 miles south of Salt Lake City The area is steeped in a rich history in the supply of mining and heavy industrial machinery The original EIMCO products have been 2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function The paper demonstrates the application of this methodology to Optimization of Solids Concentration in Iron Ore Ball Milling 2020年6月1日 (14) based upon industrial results from a 244 m internal diameter ball mill, operating under wet closed circuit grinding with a circulating load of 250% If an industrial ball mill circuit deviates from the type used by Bond in some way, the ratio of the operating to lab work index is not a fair measure of efficiencyStirred media mills in the mining industry: Material

Soft sensor of wet ball mill load parameter based on domain

2017年9月18日 CIESC Journal ›› 2018, Vol 69 ›› Issue (3): 12441251 doi: 1011949/jissn04381157 Previous Articles Soft sensor of wet ball mill load parameter based on domain adaptation with manifold regularization DU Yonggui, LI 8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect TopicsOn the other hand, dry ball milling tests were carried out in a laboratory ball mill having a 20 cm internal diameter and 5776 cm 3 volume (Figure 3(b)) with charge of 5475 g steel ball mixtures Product size distributions from wet grinding of 600

Ball Mill an overview ScienceDirect Topics

Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision 行星式球磨仪 PM 100 Wet and nanoscale grinding with the PM 100 Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, which makes further grinding in dry mode difficult By adding a liquid or dispersant the particles can be kept separated行星式球磨仪PM100德国RETSCH(莱驰)研磨仪粉碎仪2001年1月15日 On the other hand, dry ball milling tests were carried out in a laboratory ball mill having a 20 cm internal diameter and 5776 cm 3 volume (Figure 3(b)) with charge of 5475 g steel ball mixtures (PDF) Kinetics of Fine Wet Grinding in a Laboratory Ball Mill

Experimental analysis of wet mill load parameter based on

2020年12月1日 Section snippets Generation mechanism analysis of multiple channel mechanism signals The ball mill is a heavy rotating device that relies on the impact and grinding between the ball load and mineral load to crush raw ore Fig 1 shows the schematic of the generation mechanism of mechanical signal at different positions of the ball mill 2019年1月1日 Data were collected from a wide range of wet industrial grinding mills to calibrate and verify the model In total 76 data sets were generated covering the power draws of ball, SAG and AG mills in (PDF) Determination of the formal powder filling of a wet ball mill 2021年5月1日 Semantic Scholar extracted view of "A method to identify wet ball mill’s load based on CEEMDAN, RCMDE and SRNN classification" by Lirong Yang et al Experimental investigation of vibration signal of an industrial tubular ball mill: Monitoring and diagnosing Zhigang Su Peihong Wang Xiangjun Yu Z Lv Engineering, Materials A method to identify wet ball mill’s load based on

Wet Milling vs Dry Milling: The Differences, Advantages

2021年6月17日 Industrial milling is one of the most commonly used techniques in the manufacturing industry and can be divided into two categories: wet milling and dry milling To understand the difference between the two, and the challenges that come along the milling process, we first need to gain an understanding of the basics2021年5月1日 A method to identify wet ball mill’s load based on CEEMDAN, RCMDE and SRNN classification Author links open overlay panel Lirong Yang a b, Jiacheng Cai c Show more Add to Mendeley Experimental investigation of vibration signal of an industrial tubular ball mill: Monitoring and diagnosing Miner Eng, 21 (2008), pp 699710, A method to identify wet ball mill’s load based on2023年10月18日 Chapter 2: Industrial Mill Components Rubber liners are used in ball mills while metal liners are used in autogenous (AG) and semiautogenous (SAG) mills The design of the liner of a mill Mills: What are they? How are Mills used?

Kinetics of fine wet grinding in a laboratory ball mill

2001年1月15日 Grinding was carried out in the laboratory ball mill described in Table 1, at a low ball load of 20% of the mill volume filled with the ball bed and a low powder load corresponding to a formal interstitial filling of void spaces of the ball bed of U=05 These conditions were chosen since it is known that they give first order grinding kinetics for 2020年1月8日 To overcome the difficulty of accurately judging the load state of a wet ball mill during the grinding process, a method of mill load identification based on the singular value entropy of the modified ensemble empirical mode decomposition (MEEMD) and a probabilistic neural network (PNN) classifier is proposed First, the MEEMD algorithm is Load State Identification Method for Wet Ball Mills Based on material ball mill besarnya berkisar antara 80,75 – 83,58 HR A, struktur mikro yang terbentuk dari ball mill tersebut didominasi adanya karbida krom (Cr 23 C 3) yang menyebabkan meningkatnya kekerasan, kekuatan, titik lelah dan elastisitas dari ballKARAKTERISASI MATERIAL BALL MILL PADA PROSES

An innovative approach for determining the grinding

2021年1月22日 1 Introduction Grinding operation is used extensively in the industry of beneficiation, metallurgy, chemical engineering, and electric power Assisted by the impact and abrasion between media (steel ball, steel rod, gravel, ceramic ball) and ore, the grinding operation reduces the particle size in the mill [[1], [2], [3]]To produce the qualified size 2018年9月25日 CIESC Journal ›› 2019, Vol 70 ›› Issue (S1): 150157 doi: 1011949/jissn04381157 • Process system engineering • Previous Articles Next Articles Soft sensor of wet ball mill load parameters based on Soft sensor of wet ball mill load parameters based on 2022年1月1日 In this section, we have conducted a preliminary study on the wear of the grinding media during the grinding process of the ore particles in the planetary ball mill To simplify the grinding process, both the ore and the grinding medium are spherical particles, and the breakage of ore particles is ignored The density of ore and grinding media Investigation of the ball wear in a planetary mill by DEM

Wet ball price, 2023 wet ball price Manufacturers

wet ball price Select 2023 high quality wet ball price products in best price from certified Chinese Wet Ball Milling manufacturers, Wet Type Ball Mill suppliers, wholesalers and factory on MadeinChinaBall Mill Processing ability: 065615t/h Feeding size: ≤25 mm Applied material: gold ore, copper ore, cement, clinker, silica sand, feldspar, slag, quartz, gypsum, limestone, bauxite ore, calcium carbonate, etc Ball mill is a horizontal grinding mill and key equipment for grinding materials, widely used in ore flotation processing plant and powdermaking Ball mill Henan Mining Machinery CO,LTDDouble chamber ball mills for the cement industry come in various designs: For bearings, either slide or slide shoe bearings can be chosen Possible drives include gear rim/pinion, lateral, or central drives If the processing Ball mill CEMTEC double DirectIndustry

An overfilling indicator for wet overflow ball mills

2016年9月1日 The most frequently appeared residence time in the 121 sets of industrial ball mill surveys is the 3–4 min band, with an occurrence frequency of 182% A total of 678% surveys had residence time between 2 min and 7 min This residence time range can be regarded as typical in the industrial overflow ball mill operation2022年1月1日 It was found that the value of the mill diameter scaleup factor varied quite significantly with the breakage properties of the material, the size distribution of the particulate contents of the mill, the size of the desired product, and the mode of grinding (dry/wet) Therefore, ball mill scaleup models presently available need to be modified Population balance modeling approach to determining the mill 2010年9月27日 fill level of an industrial ball mill based on the vibration characteristics of the mill shell,” Minerals Engineering , vol 22, no 14, pp 12001208, 2009(PDF) Modeling of operating parameters for wet ball mill

What Is Ball Mill? Eastman Rock Crusher

2023年3月16日 1) The dry and wet ball mills have different discharge methods The discharge outlet of the dry ball mill is a straight cylinder type, which adopts grate plate mill tail discharging, and the discharge is uniform; The outlet of the wet ball mill is a trumpet type with a builtin screw device for discharging 2) Difference in auxiliary equipment2010年8月1日 Section snippets Experiment setup The experiments were performed on a laboratoryscale ball mill (XMQL420 × 450), which is a continuous grinding grid mill The mill drum is 460 mm in diameter and 460 mm in length, as shown in Fig 1The mill, driven by a threephase 212 kW motor, has maximum ball load of 80 kg, a designed pulverizing Experimental analysis of wet mill load based on vibration 2019年10月11日 To overcome the difficulty of accurately determining the load state of a wet ball mill during the grinding process, a method of mill load identification based on improved empirical wavelet transform (EWT), multiscale fuzzy entropy (MFE), and adaptive evolution particle swarm optimization probabilistic neural network (AEPSOPNN) Load State Identification Method for Ball Mills Based on

Producing Metal Powder from Machining Chips Using Ball

2023年6月27日 A ball mill is additionally utilized to grind and combine materials, commonly with spherical or cylindricalshaped grinding media such as balls or rods Numerous researchers have effectively used ball milling to produce nanostructures of various materials or to investigate structural changes in materials during ball milling [87,88,89,90,91Mill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill 2017年7月17日 Abstract: Aiming at the challenging problems such as the measurement of key load parameters of ball mill under multioperating conditions, a soft sensor model based on domain adaptation with manifold regularization (domain adaptation with manifold regularization,DAMR) for measuring wet ball mill load parameters is proposedSoft sensor of wet ball mill load parameter based on domain

球磨机百度百科

2023年8月15日 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿 2023年9月1日 1 Mineral Processing: Wet ball mills are extensively used in the mineral processing industry to grind ores and minerals for further processing They are employed in various stages of What is a wet overflow ball mill and its applications LinkedIn2022年8月11日 This study investigated the effect of grinding media on the finegrinding performance in the wet tumbling mill Comparative experiments between cylpebs and ceramic balls were conducted in a laboratory wet ball mill under various conditions, such as different total masses, total surface areas, and total numbers The results indicated that Minerals Free FullText A Comparison of the FineGrinding

Ball Mills 48 Manufacturers, Traders Suppliers

2023年10月14日 Ball MillsCPB offers state of the art ball mills:with slide shoe bearing to reduce stress in the mill shell and mill internalswith lateral gear drive and self aligning pinionwith a central lubrication systemwith large reinforced manholes (540 x 640 mm) for optimal maintenance and assembly conditionspossible installed engine performance: 2021年11月17日 This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb) Dried nanocrystal Nb powders, of high purity, with particle sizes Wet ball milling of niobium by using ethanol, determination 2021年9月5日 Several mathematical models have been developed to predict the PSDs of particulate materials, including lognormal, logistic, Gates–Gaudin–Schuhmann (GGS), and Rosin–Rammler (RR) distributions, while truncated size distributions can also be used when a particle population would have every particle smaller than a definite top size [38, 39]In Modeling of Bauxite Ore Wet Milling for the Improvement of

Ball Mill Manufacturer Neumann Machinery Company

Founded in 1984 with the acquisition of the EIMCO ball, pebble and rod mill product lines Neumann Machinery Company (NMC) is headquartered in West Jordan, Utah, in the USA just 14 miles south of Salt Lake City The area is steeped in a rich history in the supply of mining and heavy industrial machinery The original EIMCO products have been 2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function The paper demonstrates the application of this methodology to Optimization of Solids Concentration in Iron Ore Ball Milling 2020年6月1日 (14) based upon industrial results from a 244 m internal diameter ball mill, operating under wet closed circuit grinding with a circulating load of 250% If an industrial ball mill circuit deviates from the type used by Bond in some way, the ratio of the operating to lab work index is not a fair measure of efficiencyStirred media mills in the mining industry: Material