عنا

مرحبا هل يمكنني مساعدتك؟

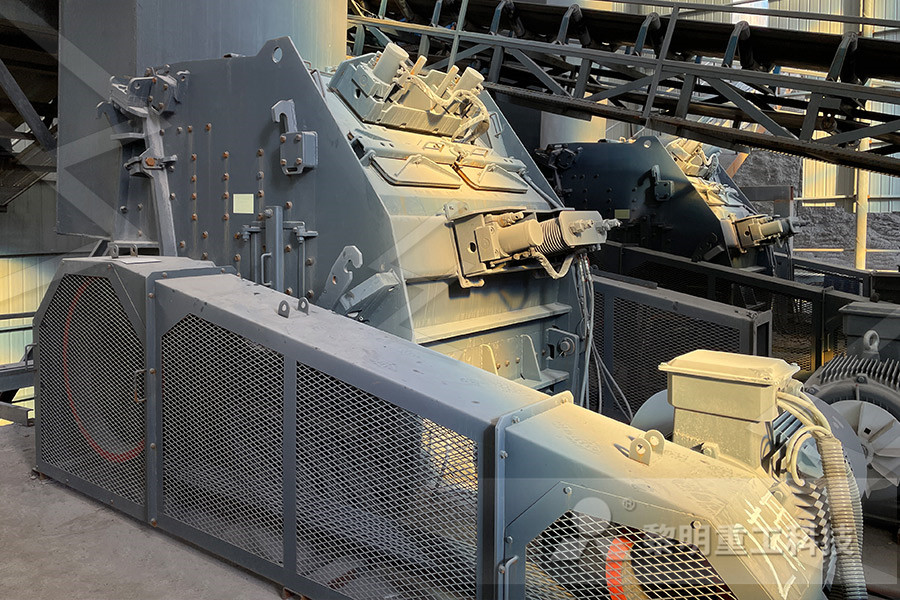

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Calculation For Vertical Roller Mills

2023-11-30T10:11:26+00:00

Analysis and Optimization of Grinding

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power Operational parameters affecting the vertical roller mill In this research work, the application of population balance model for simulation of a VRM in a cement clinker grinding circuit was investigated The residence time distribution (RTD) Modeling and simulation of vertical roller mill using

Grinding process within vertical roller mills: experiment and

2009年1月1日 The simulation calculation used a breakage function, B The results indicate that the breakage function, B, and the selection function, S, in the form of a matrix, can 2021年3月1日 Within the framework of the study’s realization, a mathematical model was developed and we presented the selected Selected Aspects of Modelling and Design 2022年1月23日 mill, coal mill, Clinker Mill and cement mill, and the vertical mill occupies a large energy consumption unit Therefore, it is necessary to optimize the multiobjective Roller Mill Based on Experimental Method mdpires

Analysis of vertical roller mill performance with changes in

2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method 2017年9月11日 Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit(PDF) Performance Evaluation of Vertical Roller 2021年11月5日 Keywords: lower rocker arm; ANSYS Workbench; finite element analysis; response surface analysis; optimization design 1 Introduction The Vertical Roller Mill (VRM) is a large piece of equipment Optimization Design of the Lower Rocker Arm of a

(PDF) Matrix Model Simulation of a Vertical Roller

2014年5月1日 Schematic of the Pfeiffer's 2800 C vertical roller mill Measured separation curves of the rotating slats separator (T 2 ) Parameter: Revolution number of rotating slats Separation2019年10月30日 Automated welding of continuous casting roller Coating with PTA welding Castolin Services Workshop Castolin Services Workshops have gained experience of welding wear parts for Vertical Roller Mills since the early 90s Today we have 7 Castolin Services Workshops worldwide, which are able to deliver in house solutions with Stateof Key Industry Program Castolin Eutectic2021年3月17日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the (PDF) An approach to measuring and modelling the

OptimizationofVerticalRawMillOperationpdf

2023年1月18日 Vertical Roller Mills Calculation of Fan Motor Power P shaft = Valid for Fan without Damper Losses Only Flow (am3/h) X Static Pr (mbar) X F dust X F dyn Efficiency X 981 X 3600 Typical: Efficiency 08 2023年1月31日 Vertical Roller Mills Calculation of Fan Motor Power Flow (am3/h) X Static Pr (mbar) X F P shaft = dust XF dyn Efficiency X 981 X 3600 Typical: Efficiency 08 F dust 10 102 F dyn 102 103 Valid for Fan without Damper Losses Only Vertical Roller Mills Calculation of Nozzle Ring Air Speed 1Optimization of Vertical Raw Mill Operation PDF Mill The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) The VRM technology was introduced in the mid'90s for grinding clinker and slag by LOESCHE (Schaefer, 2001) Fig 1 illustrates the grinding parts of a Loesche vertical roller millModeling and simulation of vertical roller mill using

Selected Aspects of Modelling and Design Calculations of Roller Mills

2021年3月1日 An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agrifood, chemical, power and construction industries were presented Quick designing of the machines required existence of adequate mathematical models Within the framework of the study’s realization, a mathematical 2021年11月5日 The lower rocker arm is an important part of the vertical roller mill and its lightweight design is of great significance for reducing the mass and production cost of the roller mill Firstly, the strength and deformation distribution of the lower rocker arm under working load were analyzed by ANSYS Workbench to determine the maximum stress Optimization Design of the Lower Rocker Arm of a Vertical Roller Mill 2012年9月27日 It is a combination of software and hardware design concept Eight optimization steps – pass schedule generation, work roll determination, backup roll diameter, mill type selection, mill window (PDF) On the Optimization Procedure of Rolling Mill Design

Optimization Design of the Lower Rocker Arm of a

2021年11月5日 The Vertical Roller Mill (VRM) is a large piece of equipment for grinding materials and is usually used in the production fields of milling slag, cement raw material, clinker, and coal With the development of social productivity, the grinding industry is making for calculations in the design process of VRMs These methods are adopted in 2017年1月1日 Jan 2016 4148 M Keyßner T Fahrland Keyßner, M and Fahrland, T: Drive selection for large Loesche vertical roller mills Cement International, 2/2016, pp 4148 Operational experience (PDF) Drives for large vertical roller mills ResearchGate2021年3月17日 This paper presents an experimental approach to measure and model the residence time distribution of vertical roller mill in cement clinker grinding circuit The dispersion model, tankinseries model, and a perfect mixer with a bypass model were employed to describe the residence time distribution A perfect mixer with a bypass An approach to measuring and modelling the residence time distribution

Analysis of vertical roller mill performance with changes in

2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical 2015) and MATLAB image analysis toolbox were used to analyze the particle size after crushing and calculate the major and minor 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the Analysis and Optimization of Grinding 2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) was employed to explore the crushing in an overflow VRM without air involved via the bondedparticle model (BPM) DEM, a numerical method to calculate motion and Analysis of vertical roller mill performance with changes in

Optimization of Vertical Raw Mill Operation PDF Scribd

2022年3月10日 Vertical Roller Mills Calculation of Fan Motor Power Flow (am3/h) X Static Pr (mbar) X F P shaft = dust XF Efficiency X 981 X 3600 Typical: Efficiency 08 F dust 10 102 F dyn 102 103 Valid for Fan without Damper Losses Only dyn Vertical Roller Mills Calculation of Nozzle Ring Air Speed 1 Mill Housing2021年1月28日 This paper deals in first place with roller mills for raw material processing For grinding coal, slag, cement, etc, adaptations to mills and systems have to be made 2 FUNCTIONS OF THE ROLLER MILL The vertical roller mill fulfills 4 main functions in one compact piece of equipment: ¢ Grinding « Drying ¢ Separation ¢ TransportHolderbank Cement engineering book Archive2016年12月19日 Vertical roller mills are not only used for grinding cement raw materials but also find an application in grinding a wide variety of coal types in cement and power plants Gebr Pfeiffer SE (GPSE) describes its vertical roller mills for coal grinding and provides a case study of an MPS225BK installed at CBR’s Lixhe cement works in BelgiumCOAL GRINDING IMPS: more than meets the eye Gebr

Vibration Analysis of a Vertical Roller Mill: Modeling and Validation

2014年7月25日 Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Due to harsh production environment and inconsistent raw Making “digital twins” for rolling processes and mill equipment should begin with the development of mathematical models of the deformation zone The deformation zone of twohigh flat mill rolling have been studied in detail, relevant models are available in many academic papers However, the same cannot be said about the most complex Calculating Power Parameters of Rolling Mill Based on Considering the equivalent elasticplastic stiffness within the rolling gap, an eight DegreeofFreedom (DOF) centralized mass model in the vertical direction for a sixroller mill is proposed Calculation flow of the friction coefficient and the rolling

Operational parameters affecting the vertical roller mill

2017年4月1日 In the airswept mode, the verticalrollermill and a high efficiency dynamic classifier are suited above each other as a single unit (Fig 1) Material is fed to the grinding chamber and transported by table rotation to the grinding gap between the fixed grinding rollers and the mill table Crushing and grinding take place by compressive grindingPDF On Dec 1, 2014, Shuixuan Chen and others published Calculation of rolling pressure distribution and force based on improved Karman equation for hot strip mill Find, read and cite all the Calculation of rolling pressure distribution and force based 2017年4月1日 Abstract Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment Operational parameters affecting the vertical roller mill

Roller Mill Based on Experimental Method mdpires

2022年1月23日 mill, coal mill, Clinker Mill and cement mill, and the vertical mill occupies a large energy consumption unit Therefore, it is necessary to optimize the multiobjective parameters of the VRM in order to improve the grinding performance and reduce energy consumption The present work focuses on the grinding performance of an overflow 2013年3月1日 C Obry KarlHeinrich Zysk Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite cements From the energy aspect they are (PDF) Cements ground in the vertical roller mill fulfil the 2023年11月7日 The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) test data, backcalculation ,or Modeling and simulation of vertical roller mill using

(PDF) Increase productivity of vertical roller mill

2021年1月29日 FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320 Flyash is a major supply for any cement plant now a days because every producer wants to produce more PPC than OPC due to profitability 2017年10月27日 Figure1 Vertical roller mill for cement grinding [13] VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal revolving grinding table To enhance comminution, the axes of table and rollers do not traverse in the plane of the table and approximately 150 inclination angles betweenPROCESS CONTROL FOR CEMENT GRINDING IN 2009年1月1日 Abstract Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation of the grinding process in vertical roller mills was carried out The simulation calculation used a breakage function, B The results indicate that the breakage function, B, and Grinding process within vertical roller mills: experiment and

Selected Aspects of Modelling and Design Calculations of Roller Mills

2021年3月1日 An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agrifood, chemical, power and construction industries were presented Quick designing of the machines required existence of adequate mathematical models Within the framework of the study’s realization, a mathematical 2021年1月1日 A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true Vertical roller mill The feed is ground by pressure and friction between the horizontal rotating table and 4 to 6 grinding rollers in the VRM These rollers are Review on vertical roller mill in cement industry its 2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinderrollermill,highpressurerollermill,Raymond mill, and column mill Vertical Roller MillRoller Mill Springer

Application of perfect mixing model for simulation

2017年5月26日 Vertical roller mills (VRMs) are wellestablished grinding equipment for various tasks in the coal and cement industry There are few studies on simulation of VRMs2023年9月18日 The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal Grinding pressure can be adjusted to account for variations in coalA Comparison of Three Types of Coal Pulverizers2009年1月31日 The vertical roller mill (VRM) which has gained wide acceptance in the cement industry and is used for grinding raw materials (mainly limestone), is a promising alternativeGrinding process within vertical roller mills ResearchGate

Industrial application of system integration updated

The vertical roller mill, also called vertical mill, which is widely used in the modern cement industry because it has high grinding efficiency, strong drying capacity and simple system configuration If the modified system fan is updated to adapt to the new operating conditions, a rough calculation shows that the fan power consumption 2021年11月14日 Vertical Roller Mills • Do not believe screen values unless you have checked them • Continuously change Process Parameters and document results to find Optimum • Optimum is highest capacity at lowest power consumption • Be sensitive to changes of feed material and adapt parameters • Focus on Relevant Process optimizationofverticalrawmilloperationpdf Vertical Roller Mills 2017年9月14日 ball mills for cement grinding, a 245 t/h vertical roller mill was added The rating of the MVR mill of the type MVR 5000 R4 is based on grinding tests conducted at the test station of the Gebr Pfeiffer SE in Germany There are several pilot plants available with MPS and MVR mills which are operated in the same way as industrial plantsCEMENT Gebr Pfeiffer

(PDF) Design and Realization Of Roller Mill Control System

2012年12月31日 Abstract and Figures a Distributed Control System (DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT The results demonstrate the 2015年11月19日 2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product flat, sections or hollow sections rolling (iii) Direction of rolling lengthwise, transverse, and skew rolling (iv) Mode of rolling mill operation continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed When two rolls of Introduction to Rolling Process Cambridge University 2019年10月30日 Automated welding of continuous casting roller Coating with PTA welding Castolin Services Workshop Castolin Services Workshops have gained experience of welding wear parts for Vertical Roller Mills since the early 90s Today we have 7 Castolin Services Workshops worldwide, which are able to deliver in house solutions with Stateof Key Industry Program Castolin Eutectic

(PDF) An approach to measuring and modelling the

2021年3月17日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the 2023年1月18日 Vertical Roller Mills Calculation of Fan Motor Power P shaft = Valid for Fan without Damper Losses Only Flow (am3/h) X Static Pr (mbar) X F dust X F dyn Efficiency X 981 X 3600 Typical: Efficiency 08 OptimizationofVerticalRawMillOperationpdf2023年1月31日 Vertical Roller Mills Calculation of Fan Motor Power Flow (am3/h) X Static Pr (mbar) X F P shaft = dust XF dyn Efficiency X 981 X 3600 Typical: Efficiency 08 F dust 10 102 F dyn 102 103 Valid for Fan without Damper Losses Only Vertical Roller Mills Calculation of Nozzle Ring Air Speed 1Optimization of Vertical Raw Mill Operation PDF Mill

Modeling and simulation of vertical roller mill using

The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) The VRM technology was introduced in the mid'90s for grinding clinker and slag by LOESCHE (Schaefer, 2001) Fig 1 illustrates the grinding parts of a Loesche vertical roller mill2021年3月1日 An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agrifood, chemical, power and construction industries were presented Quick designing of the machines required existence of adequate mathematical models Within the framework of the study’s realization, a mathematical Selected Aspects of Modelling and Design Calculations of Roller Mills2021年11月5日 The lower rocker arm is an important part of the vertical roller mill and its lightweight design is of great significance for reducing the mass and production cost of the roller mill Firstly, the strength and deformation distribution of the lower rocker arm under working load were analyzed by ANSYS Workbench to determine the maximum stress Optimization Design of the Lower Rocker Arm of a Vertical Roller Mill

(PDF) On the Optimization Procedure of Rolling Mill Design

2012年9月27日 It is a combination of software and hardware design concept Eight optimization steps – pass schedule generation, work roll determination, backup roll diameter, mill type selection, mill window 2021年11月5日 The Vertical Roller Mill (VRM) is a large piece of equipment for grinding materials and is usually used in the production fields of milling slag, cement raw material, clinker, and coal With the development of social productivity, the grinding industry is making for calculations in the design process of VRMs These methods are adopted in Optimization Design of the Lower Rocker Arm of a 2017年1月1日 Jan 2016 4148 M Keyßner T Fahrland Keyßner, M and Fahrland, T: Drive selection for large Loesche vertical roller mills Cement International, 2/2016, pp 4148 Operational experience (PDF) Drives for large vertical roller mills ResearchGate