عنا

مرحبا هل يمكنني مساعدتك؟

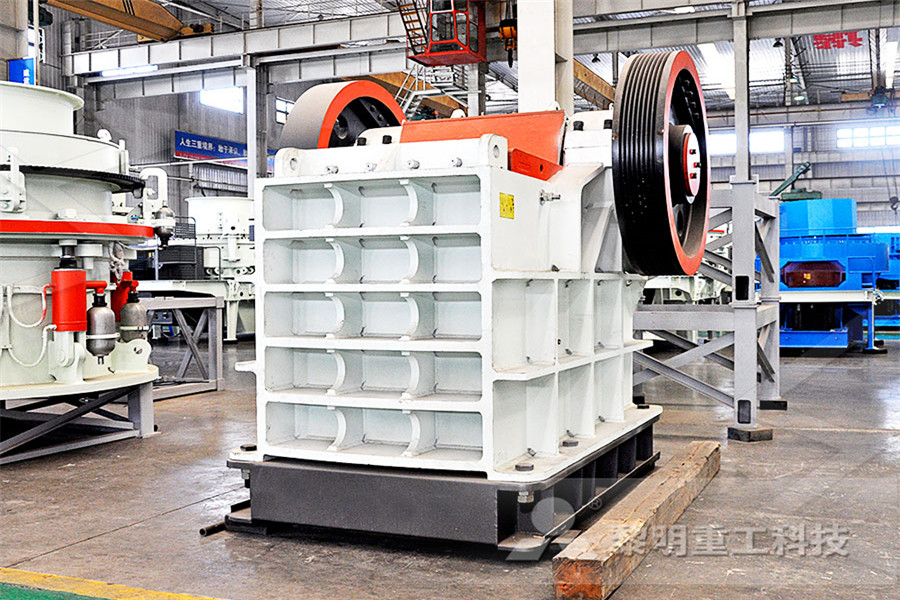

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

beneficiation of chromite ore

2020-08-09T15:08:50+00:00

Chrome ore beneficiation challenges opportunities – A

2011年4月1日 The detailed study of chromite ore beneficiation processes reveals that the opportunities still exist to recover chromite values from the low/subgrade ores and tailings using the conventional beneficiation processes2023年10月1日 Currently, chromite ore resources around the globe are estimated to be between 9 and 12 billion tonnes ( Kogel et al, 2006, OCC, 2014, USGS, 2015) Chemical beneficiation of chromite ore to improve the 2023年1月1日 Huge quantity of raw chromite ore is being mined and beneficiated in various chrome ore beneficiation plants throughout the world to cater the customized Chromite ore beneficiation: prospects and challenges

Chrome ore beneficiation challenges

2011年4月1日 This article reviews the major process flow sheets in practice for the recovery of chromite values from various types of ores 2011年4月1日 This article reviews the major process flow sheets in practice for the recovery of chromite values from various types of ores and critical issues related to Chrome ore beneficiation challenges opportunities – A 2023年1月1日 This chapter gives an integrated overview of mining, beneficiation technologies along with effluent treatment and its challenges and finally discussed some Chromite ore beneficiation: prospects and challenges

[PDF] INVESTIGATION OF CHROMITE ORE BENEFICIATION

2023年2月9日 In this study, beneficiation possibilities of the representative chromite ore taken from the Tokat Province with a laboratory type jig, spiral concentrator, shaking 2017年8月28日 Keywords: tailings; mineralogy; chromites; beneficiation 1 Introduction Chromite is the main source of chromium metal and an important raw material for the Quantitative mineralogical characterization of chrome Request PDF On Jan 1, 2023, C Raghu Kumar and others published Chromite ore beneficiation: prospects and challenges Find, read and cite all the research you need Chromite ore beneficiation: prospects and challenges

Chrome ore beneficiation challenges opportunities A

This article reviews the major process flow sheets in practice for the recovery of chromite values from various types of ores and critical issues related to chromite ore beneficiation 2023年2月9日 The shaking table gave the best results for chromite beneficiation and a concentrate of 4702% Cr2O3 grade and 9429% recovery were obtained by using a 03+0106 mm particle size fraction It was observed that concentrates with saleable grade could be obtained as a result of the beneficiation of chromite ore with a spiral concentrator[PDF] INVESTIGATION OF CHROMITE ORE BENEFICIATION 2017年8月28日 chromite concentrate with 4529wt% Cr2O3 and a Cr:Fe mass ratio of 185 can be produced from these lowgrade chromite ore beneficiation plant rejects Keywords: tailings; mineralogy; chromites; beneficiation 1 Introduction Chromite is the main source of chromium metal and an important raw material for the production of stainless steel,Quantitative mineralogical characterization of chrome

Relationship between process mineralogical characterization

2021年10月22日 Process mineralogy of lowgrade laterite nickel ore in Indonesia was systematically characterized and the beneficiation process of mineral components such as limonite, serpentine and chromite was studied on the basis of process mineralogy The results show that the lowgrade laterite nickel ore is a typical weathering sedimentary 2020年12月10日 The Sukinda Valley ore samples contain 50% chromite ore is economic But the >7% of CR (III) ore in the tailings and overburden shall warrant the future expected exorbitant Cr (VI) in the geobio (PDF) Evaluation of Chromite Recovery from Shaking Table 2018年6月20日 Chromite beneficiation operations in Sukinda valley (India) produce large amounts of tailings, which are stored in open air In this study, bioleaching experiments were carried out in batch reactors with Acidithiobacillus thiooxidans or Pseudomonas putida in order to determine the potential leachability of metals contained in these tailings due to Free FullText (Bio)leaching Behavior of Chromite Tailings

HighIntensity Magnetic Separation Processing of

2016年6月1日 ore beneficiation, specific gravity and sizebased separations are the most convenient and cost effective methods in India (Murthy et al 2011; Tripathy et al 2012)2020年5月19日 Chromite deposits occur in the form of discontinuous bands, lenses, and pockets in different host rock associations Chrome ore beneficiation Most of the chrome ores around the world are beneficiated by gravity concentration techniques A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections:Process optimization of a chrome ore gravity 2014年10月15日 The beneficiation of low grade (Cr2O3% 2688) chromite ore has been investigated using wilfley table Optimization has been carried out using boxbehnken statistical design (BBD)(PDF) BENEFICIATION OF MAGNETITE RICH CHROMITE ORE

Journal of Environmental Analytical Chemistry PhilArchive

Beneficiation of a low grade chromite ores is an essential step towards optimum utilization of natural resources Some of the old practices like handpicking, size reduction and screening are still in use to upgrade and prepare chromite ore for use in the industry During mining, ferruginous and siliceous chromite ore fines are created as2011年4月1日 Commercial chromite ore beneficiation processes Pure chromium is difficult to produce since it is readily contaminated by many other elements Huge quantity of raw chromite ore is being mined and beneficiated in various chrome ore beneficiation plants throughout the world to cater the customized needs of various ferro alloy plants During Chrome ore beneficiation challenges opportunities – A 2 天之前 the beneficiation of chromite ore, about 50% of the total feed is discarded into tailings which therefore consist of huge quantity of chromite values in the ultrafine sizes The beneficiation of tailings is a necessary step from the point of view of mineral conservation, utilization of scarceEvaluation of Advanced Gravity and Magnetic

Kinetic Studies on the Reduction of Iron Oxides in LowGrade Chromite

2018年6月4日 In a novel method of beneficiation of lowgrade chromite ore, nuggets, 25 mm in diameter and 10 mm long, made of chromite ore and coke fines, are subjected to partial reduction A significant degree of reduction of iron oxide is observed at temperatures of 1373–1523 K up to a reduction time of 240 min, and subsequent magnetic separation 2016年3月23日 ABSTRACT Mineral and morphological characteristics of chromite ore strongly affect the separation efficiency while upgrading the lowgrade deposits Usually, chromite ore enrichment is carried out by using gravity separation due to highconcentration criterion between chromite and other minerals However, chromite ore from Sukinda Processing of Ferruginous Chromite Ore by Dry High 2023年3月20日 The aim was to identify all major gangue impurities, the degree of chromite liberation, and possible beneficiation options The bulk material assayed 405% Cr2O3 with the major impurities being Automated and Quantitative Mineralogy Applied to Chromite Ore

Relation between grade (% Cr2O3) and Cr:Fe ratio of

Beneficiation of chromite ore has been done by many researchers to improve the Cr/Fe ratio using different beneficiation techniques [3][4] [5] [6][7] G P Gallios et al have studied the Tevfik in 2007 produced a concentrate by Humphrey spiral with 546% Cr 2 O 3 and 949% recovery from Topraktepe chromite ore with an average composition of 4768% Cr 2 O 3 [21] On the other hand, the magnetic separation method which is used for separating magnetic from nonmagnetic minerals according to their magnetic susceptibility, is Evaluation of Chromite Recovery from Shaking Table Tailings 2015年4月11日 A chromite concentrate with 4529wt% Cr2O3 and a Cr:Fe mass ratio of 185 can be produced from these lowgrade chromite ore beneficiation plant rejects Mineralogical characterization and liberation of valuable minerals are primary concerns in mineral processing industries The present investigation focusesQuantitative mineralogical characterization of chrome ore beneficiation

Relationship between process mineralogical characterization

2021年10月1日 Process mineralogy of lowgrade laterite nickel ore in Indonesia was systematically characterized and the beneficiation process of mineral components such as limonite, serpentine and chromite was 2013年7月10日 DOI: 101016/JMINPRO201304008 Corpus ID: ; Characterisation and separation studies of Indian chromite beneficiation plant tailing @article{Tripathy2013CharacterisationAS, title={Characterisation and separation studies of Indian chromite beneficiation plant tailing}, author={Sunil Kumar Tripathy and Characterisation and separation studies of Indian chromite 2016年12月31日 Chromite ore (FeOCr 2 O 3) is the most important mineral occurrence of chromium, and some deposits are reported in Anka Local Government Area of Zamfara State Recovery of chromite values, by Chromite Request PDF ResearchGate

[PDF] Characterization and Beneficiation of Anka Chromite Ore

2007年10月20日 Chromium is largely used as alloying elements in steels for production of stainless steels It is added in form of ferrochromium, which is presently imported from Russia and Germany to meet the need of Nigerian Steel Industry Chromite ore (FeOCr2O3) is the most important mineral occurrence of chromium, and some deposits are reported 2012年10月12日 Chromite ore beneficiation plants in Sukinda region treat selected rich ores (A38% Cr203) with a view to producing concentrate of about 50% Cr203 as directly marketable grade for export and domestic industries This has resulted rejection and piling of huge quantities ofBeneficiation of Low Grade Chromite Ores from SukindaFigure 3—Conventional process flow sheet for chromite ore beneficiation Figure 4—Beneficiation of Indian chromite ores ˙ ˛˘ ˙ 264 MAPRIL 2020 VOLUMEProcess optimization of a chrome ore gravity

Processing of LowGrade Chromite Ore for Ferroalloy

2020年9月11日 to subhedral grains of chromite and quartz grains (Fig 2b) with minor amount of CrMica (fuchsite) and kaolinite Fine dusts of chromite within quartz (Fig 2c) and micron size quartz/silicates within chromite grains (Fig 2d) are ubiquitously observed, which inhibits easy liberation during its processing XRD pattern of the chromite ore shows2022年1月8日 Chromite ore is the only commercial source of chromium in the metallurgical industries [1] It occurs as a chromium spinel, a complex mineral containing chromium, iron, aluminium and magnesium in changeable proportions depending upon the deposit [2] Chromite deposits can be estimated using geostatistics and geotechnical methods [3,4]PAPER OPEN ACCESS You may also like The ore beneficiation process involves the removal of gangue mineral/earthly impurities from ore mineral through gravity and magnetic separation processes Wilfley Shaking Table was used for gravity separation to remove gangue mineral as it is more economical and easier to exercise The main compd of the chromite ore was a spinel Development and Characterization of Natural Chromite

Beneficiation of low grade chromite for preparation of

2020年5月6日 taken for laboratory scale beneficiation Characteristics of the chromite samples Four chromite samples from rejected dumps and overburden materials of a chromite mine, were collected for their beneficiation All the four samples are nonmagnetic, soft in nature and black to brownish black in colour FIG 1 Photomicrograph Common 1988年1月1日 Lower Chromitemineralogy and processing 239 grades now make beneficiation of much of the ore essential, gravity concentration (Heavy Medium Separation and tabling) being used with flotation [9] Research There has been much research activity in recent years aimed at exploiting the hitherto untapped reserves of lowgrade, low Cr:Fe Chromite mineralogy and processing ScienceDirect2019年10月29日 The low chromiumtoiron ratio of chromite ores is an important issue in some chromite deposits The value of the chromite ore is indeed dictated in the market by its iron, as well as its chromium content In the present study, a chromite concentrate was reprocessed by gravity (spiral concentrator) and magnetic separation to enhance the Improving the Quality of Ferruginous Chromite Concentrates Via Physical

Minerals Free FullText An Overview of Currently Applied

2023年6月13日 In conclusion, considering the inert nature of the solid materials generated during chromite ore beneficiation, there are few concerns regarding the current management thereof other than dust dispersion and the potential of Cr(VI) accumulation in tailings dams The main issue regarding chromite beneficiation is the volume of material being Beneficiation of chromite ore using selective chlorination was successfully employed to improve the low grade ore in South Africa The Cr:Fe ratio attained, using this approach was 20:1 [9]CHARACTERIZATION AND BENEFICIATION OF ANKA 2022年9月1日 Karagedik Chromite Concentrator of the ETI Holding Co, which is located in Fethiye (south Turkey), has been producing chromite concentrate assaying 47–48 % Cr2O3 from chromite ores containing A study on the recovery of fine chromite from

Selective Flocculation of Chromite Tailings SpringerLink

2021年1月23日 21 Materials Tata Steel Ltd, has its Chromite Ore Beneficiation (COB) plant at Sukinda zone, Jajpur district of Odisha state, India It was observed that during beneficiation, substantial quantity of chromite tailings was produced and these tailings were stocked in the dam [2, 3]For research work, tailing sample was collected from different In this study, the possibility of beneficiation of chromite in the ElazigKefdag region by MultiGravity Separator was investigated The results of beneficiation studies showed that commercial concentrate containing 5214% Cr2O3 was obtainable with a 6957% rate of recovery The optimum operation parameters determined for the concentration of [PDF] Beneficiation of ElazığKefdağ Chromite by Multi 2020年8月12日 A process mineralogical study based on three texturally and mineralogically different chromitebearing ore types at the Nkomati nickel mine was undertaken, with focus on chromite Chromite is a byproduct of the NiCuCoPGE ore at Nkomati Nickel mine These being the PCMZMG (mediumgrade NiCu sulphide silicate A Process Mineralogical Evaluation of Chromite at the

Process optimization of a chrome ore gravity concentration

A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: > Communition (for preparing the material for the subsequent unit operations) > Concentration (classification and beneficiation) The beneficiation process flow sheet varies from location to location according to the ore characteristics2021年9月15日 To enrich the chromite values, researchers have treated the COPT in the different dry and wet beneficiation processes, and the summary of these studies are listed in Table 1 Most of these enrichment routes are stated to produce a marketable chromiterich concentrate, but it generates more ultrafine tailings, which is again a waste for industry Efficient utilization of nickel rich Chromite Ore Processing 2021年9月15日 To enrich the chromite values, researchers have treated the COPT in the different dry and wet beneficiation processes, and the summary of these studies are listed in Table 1Most of these enrichment routes are stated to produce a marketable chromiterich concentrate, but it generates more ultrafine tailings, which is again a waste for industry Efficient utilization of nickel rich Chromite Ore Processing

(PDF) Characterisation and Preconcentration of Chromite

2009年1月1日 The Tata Steel Chrome Ore Beneficiation (COB) plant is generating 50 tph of tailings assaying 17% Cr 2 O 3 A critical review on practice of the plant operating personnel is concerned in the grade 2016年11月4日 Also the efficiency of chromite beneficiation for magnetic and shaking table tests was changed between 4070 % Schematic view of VPGHMS (Url 1) Plants tailings representative grade depend on (PDF) Recovery of Chromite from Processing Plant Tailing by 2023年2月9日 The shaking table gave the best results for chromite beneficiation and a concentrate of 4702% Cr2O3 grade and 9429% recovery were obtained by using a 03+0106 mm particle size fraction It was observed that concentrates with saleable grade could be obtained as a result of the beneficiation of chromite ore with a spiral concentrator[PDF] INVESTIGATION OF CHROMITE ORE BENEFICIATION

Quantitative mineralogical characterization of chrome

2017年8月28日 chromite concentrate with 4529wt% Cr2O3 and a Cr:Fe mass ratio of 185 can be produced from these lowgrade chromite ore beneficiation plant rejects Keywords: tailings; mineralogy; chromites; beneficiation 1 Introduction Chromite is the main source of chromium metal and an important raw material for the production of stainless steel,2021年10月22日 Process mineralogy of lowgrade laterite nickel ore in Indonesia was systematically characterized and the beneficiation process of mineral components such as limonite, serpentine and chromite was studied on the basis of process mineralogy The results show that the lowgrade laterite nickel ore is a typical weathering sedimentary Relationship between process mineralogical characterization 2020年12月10日 The Sukinda Valley ore samples contain 50% chromite ore is economic But the >7% of CR (III) ore in the tailings and overburden shall warrant the future expected exorbitant Cr (VI) in the geobio (PDF) Evaluation of Chromite Recovery from Shaking Table

Free FullText (Bio)leaching Behavior of Chromite Tailings

2018年6月20日 Chromite beneficiation operations in Sukinda valley (India) produce large amounts of tailings, which are stored in open air In this study, bioleaching experiments were carried out in batch reactors with Acidithiobacillus thiooxidans or Pseudomonas putida in order to determine the potential leachability of metals contained in these tailings due to 2016年6月1日 ore beneficiation, specific gravity and sizebased separations are the most convenient and cost effective methods in India (Murthy et al 2011; Tripathy et al 2012)HighIntensity Magnetic Separation Processing of 2020年5月19日 Chromite deposits occur in the form of discontinuous bands, lenses, and pockets in different host rock associations Chrome ore beneficiation Most of the chrome ores around the world are beneficiated by gravity concentration techniques A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections:Process optimization of a chrome ore gravity

(PDF) BENEFICIATION OF MAGNETITE RICH CHROMITE ORE

2014年10月15日 The beneficiation of low grade (Cr2O3% 2688) chromite ore has been investigated using wilfley table Optimization has been carried out using boxbehnken statistical design (BBD)Beneficiation of a low grade chromite ores is an essential step towards optimum utilization of natural resources Some of the old practices like handpicking, size reduction and screening are still in use to upgrade and prepare chromite ore for use in the industry During mining, ferruginous and siliceous chromite ore fines are created asJournal of Environmental Analytical Chemistry PhilArchive2011年4月1日 Commercial chromite ore beneficiation processes Pure chromium is difficult to produce since it is readily contaminated by many other elements Huge quantity of raw chromite ore is being mined and beneficiated in various chrome ore beneficiation plants throughout the world to cater the customized needs of various ferro alloy plants During Chrome ore beneficiation challenges opportunities – A