عنا

مرحبا هل يمكنني مساعدتك؟

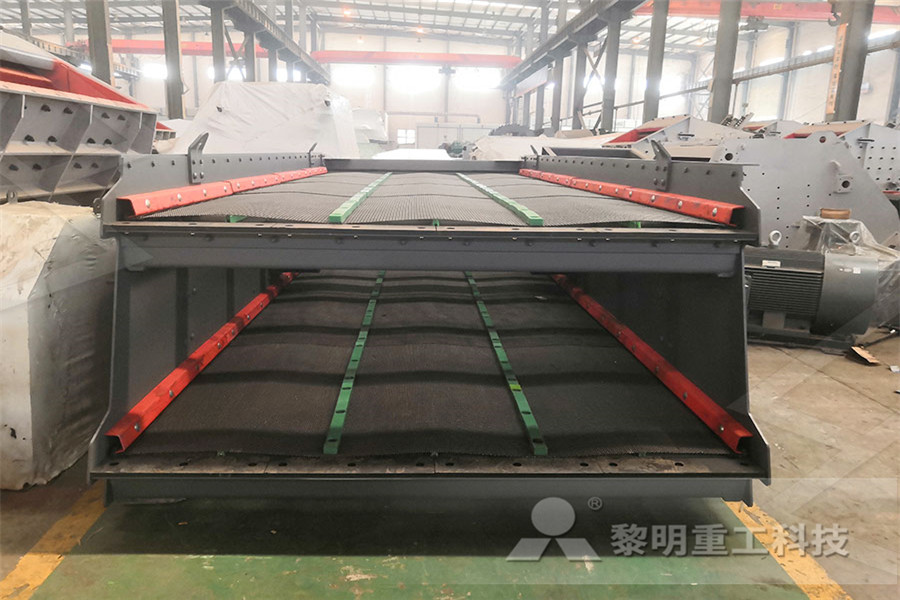

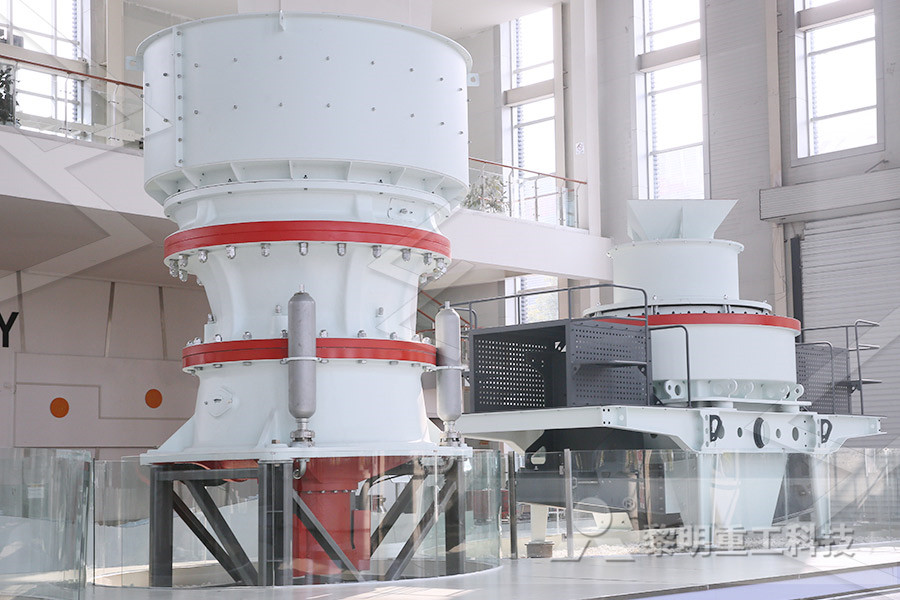

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

raw mill technical parameters

2020-03-22T19:03:20+00:00

/ raw mill technical parametersmd at main

Contribute to changjiangsx/ development by creating an account on GitHub2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The Operational parameters affecting the vertical roller mill 2021年1月22日 PDF In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total(PDF) A Survey and Analysis on Electricity Consumption of Raw

Minerals Free FullText Analysis and

2022年1月23日 There are usually four kinds of VRMs in the cement production line, including raw meal mill, coal mill, Clinker Mill and cement mill, and the vertical mill occupies a large energy consumption unit 2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 216 m roller diameter with 330 t/h capacity (made by LOESCHE Company Modeling of energy consumption factors for an industrial 2017年4月1日 A recent experimental study on parameters affecting the VRM performance shows a correlation between product fineness and dynamic separator speed, mill Operational parameters affecting the vertical roller mill

Industrial : Optimization for the Cement Industry ABB

2021年2月16日 the grinding circuit of a raw mill are an increase in output and a reduction in power consumption Expert Optimizer has been successfully applied in more than 90 2022年3月6日 Abstract: The vertical mill is a key part of the cement raw material preparation process, and it has an impact on the quality and energy consumption of the Causal analysis of vertical mill process failure based on This article presents a study on the use of machine learning models to predict kiln process fan vibrations based on process fan running parameters The study tested three different Raw mill fan running parameters Download Scientific

8VLQJ$VSHQ 3OXV6LPXODWRU IOPscience

the raw mill studied using Aspen plus simulator modelling technique was found to be 214% It was found that the difference in exergy efficiencies of the simulation results of the three 2018年12月10日 The raw mill considered in this study is located in a cement plant located in Gaziantep, Turkey The plant is a double chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 102 tons/h The mill diameter is 4000 mm and the grinding chamber length is 9,950 mm (Table 1)DETERMINATION OF CORRELATION BETWEEN SPECIFIC 2019年11月13日 The cement industry is one of the most intensive energy consumers in the industrial sectors The energy consumption represents 40% to 60% of production cost Additionally, the cement industry Parametric Studies of Cement Production

(PDF) Parametric Studies of Cement Production Processes

2020年2月15日 The most important kiln controlling parameters are clinker production rate, fuel flow rate, specific heat consumption, secondary air temperature, kiln feedend temperature, preheater exhaust gas 2017年10月27日 of the raw material [1, 2] For VRM the production capacity denotes both the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table PROCESS CONTROL FOR CEMENT GRINDING IN 2023年10月7日 from similar raw materials in a roller mill – the most common design in service with mills Physical indicators of the powders, thermophysical properties and biotechnological parameters were UDC 66476 DOI: 1015587/270654482022 RESEARCH

UDC 66476 DOI: 1015587/270654482022 RESEARCH

2023年7月22日 from similar raw materials in a roller mill – the most common design in service with mills Physical indicators of the powders, thermophysical properties and biotechnological parameters were 2021年1月19日 Our paper presents the hammer mill working process optimization problem destined for milling energetic biomass (MiscanthusGiganteus and Salix Viminalis) For the study, functional and constructive parameters of the hammer mill were taken into consideration in order to reduce the specific energy consumption The energy Sustainability Free FullText Optimization Issues of a Hammer Mill This study proposes a method for modeling the Vertical Roller Mill (VRM) to predict residue 90 micron and residue 200 micron of the raw meal product using Back Propagation Neural Network (BPNN) The modelling step is input preparation, Artificial Neural Network (ANN) structure determination, optimizer and loss function selection, training ANN and model Modeling Vertical Roller Mill Raw Meal Residue by Implementing Neural

(PDF) Effects of Mill Speed and Air Classifier Speed on

2021年6月29日 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement The research focuses on the mill speed as well as air classifier speed effect on the two Contribute to changjiangsx/ development by creating an account on GitHub/ raw mill technical parametersmd at main2012年6月1日 The analysis and performance assessment of a raw mill indicate that the grinding process involves energy and exergy losses and the process is affected by certain parameters The main results of the study can be summarized as follows: • The first law efficiency of the raw mill is determined to be 615% while the second law efficiency is Reducing energy consumption of a raw mill in cement industry

On Simultaneous Optimal Control of Raw Material

1976年9月1日 T1B4 ON SIMULTANEOUS OPTTIMAL CONTROL OF RAW MATERIAL BLENDING AND A BALL GRINDING MILL L Keviczky R Haber Department of Automation, Technical University Budapest, Budapest, Hungary J Kolostori Cement and Lime Works, Vac, Hungary M Hilger Institute for Electrical Automation, Budapest, Hungary Committee of the Technical Association of the Pulp and Paper Industry (TAPPI) recently surveyed members of the industry to find out what proc Rawi Mill* Raw Mill Raw Mill Raw Mill Raw Mill Integrated A Kraft pulp, paper 3 Avg 106 71 75 30 95 20 17 73 12 08 Max 270 148 160 36 900 40 40 15 15 15WATER QUALITY REQUIREMENTS FOR THE PAPER 2021年1月1日 Ball mill is a kind of raw material processing machinery which plays the role of grinding Its working principle is that the movement and force are transmitted to the barrel of ball mill through (PDF) Design of Threechamber Ball Mill ResearchGate

SUPPLY AND VALUE CHAIN ANALYSIS OF RICE MILL

2016年1月12日 In case of automatic rice mill, about 30% of machinery and equipment (boiler, dryer, huller, paddy separator, polisher, sheller, heater, motor etc) is supplied to auto rice mill owners Rest of the machines and equipments are manufactured locally Rice mill equipment production channel: This channel consists of raw materials importers (Dhaka),2019年8月18日 Analysis of Various Cement grinding Systems with Respect to Power Consumption keeping same quality ParametersMTech Thesis Repor Download as a PDF or view online for free The raw mix is then ground in a raw mill and subsequently burned in a rotary kiln at a temperature around 1,450°C During the burning process, the raw Analysis of Various Cement grinding Systems with RespectContribute to 2023/ development by creating an account on GitHub/ raw grinding mill technical specifi ionmd at main

Reducing energy consumption of a raw mill in cement industry

2012年6月1日 Several grinding methods are available in cement industry depending upon the material to be ground In cement production process, about 26% of the total electrical power is used in grinding the raw materials During grinding process, the energy obtained from the rotary burner is consumed In this study, the first and second law analysis of a 2012年12月31日 Abstract and Figures a Distributed Control System (DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT The results demonstrate the (PDF) Design and Realization Of Roller Mill Control System2021年1月22日 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw (PDF) A Survey and Analysis on Electricity Consumption of Raw

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日 These parameters are thoroughly studied in Technology Books 7th Edition 2006 450 p 50 Y a n g, J, Ball mills can grind a wide range of materials, including metals, ceramics, and PDF On Jun 30, 2016, Md Saiful Islam and others published Quality Control of Raw Materials for Poultry Feed Find, read and cite all the research you need on ResearchGate(PDF) Quality Control of Raw Materials for Poultry 2017年4月1日 Abstract Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment Operational parameters affecting the vertical roller mill

Environmental Consequences of Pulp and Paper Manufacture

Disposal of solid waste, recycling of fibres and use of land and forest are gaining attention Other effects of a pulp mill on the nearby society are smell, noise and influence of traffic related to the transport of raw materials and products Table 31 shows parameters important to demonstrating continuous improvements towards a minimum impact 2018年9月26日 A laboratoryscale tumbling rod mill was designed for this study, and six operative parameters were tested and analyzed in order to detect the main influences on the mill product, attending to (PDF) Analysis of process of grinding efficiency in ball and rod mills The crushed raw materials are mixed and stored for homogenization purpose, then milled together using raw mill (ball or vertical) to produce ‘raw meal’ under a strict quality control of the material chemistry Hot flue gases coming from the rotary kiln, which is in the opposite direction with the material flow, preheat the8VLQJ$VSHQ 3OXV6LPXODWRU IOPscience

Every KPI you should use in Cement Industry

Kiln Department – Raw meal silo outlet to clinker silo inlet Cooler exhaust stack to kiln stack (excl raw mill gas path) Including bypass system Cement Mill Department – Clinker silo outlet to cement silo inlet Packing Department – Cement silo outlet to cement loading (bulk and bag) Including weighing scales2021年4月22日 Ponding system or land application techniques are widely used at industrial scale to treat palm oil mill effluent (POME) prior to discharge to the environment POME is considered as one of the major problems that has generated voluminously from the palm oil industries The main purpose of this article is to organize the scattered available Palm Oil Mill Effluent Treatment Processes—A ReviewThe raw material mill is a key equipment for further pulverizing materials after being crushed by a crusher and mixed with additives It is primarily used for grinding raw materials in cement plants, and can also be utilized for grinding various ores and other grindable materials in industries such as power generation, metallurgy, and chemical engineeringCement Raw Mill Cement Raw Material Mill in Cement

Feed Mills Process Parameters Feed Mill Management Lark

Temperature range should be 7585 degrees Steam pressure at boiler should be 8595 kg/cm2 Steam pressure after PRV should be 20 to 25 kg/cm2 Steam should be Dry Saturated PDI of Pellets should be more than 85% Specific energy consumption of the pellet mill should not be more than 15 units/ton Cooling2012年6月1日 According to their study, the energy and exergy efficiencies are determined to be 843% and 252%, respectively Atmaca and Kano glu [17] also studied the raw mill in cement industry They Reducing energy consumption of a raw mill in cement industry2023年8月1日 parameters of the raw mill dynamics and their uncertainty as well is analytically described in [8] The dynamical parameters values are depicted in Table 1 Table 1 Average andEffective Optimization of the Control System for the

Full article: Comparative Analysis of Production Processes

2023年1月13日 This study was conducted in a yarn spinning mill located in Bangladesh This work produced the following four types of ringspun yarns – carded, combed, semicombed by reduced noil extraction (948%), and semicombed by (50:50) carded and combed sliver mixing in a running spinning mill2023年8月4日 from similar raw materials in a roller mill – the most common design in service with mills Physical indicators of the powders, thermophysical properties and biotechnological parameters were UDC 66476 DOI: 1015587/270654482022 RESEARCH 2021年2月8日 421 technical level 32 422 Organization level 37 423 Commercial level 40 43 Reading and interpretation of ISO/IEC 17025:2005 41 44 A road map for building a high quality system 50 45 First situation: Routine standalone feed analysis laboratory 50 ance among these parameters, the animal’s nutritional requirements must be The feed analysis laboratory: Establishment and quality

(PDF) PRODUCTION AND PRODUCTIVITY IMPROVEMENT THROUGH EFFICIENCY SUGAR MILL

2018年3月21日 Improving the technical efficiency of the factory resulted in increased productivity of raw materials of 0029 tons white crystal sugar/tons, productivity of machine work hours of 529 white 2016年9月1日 The raw mill fan is typically a centrifugal fan, which draws air through a duct and then pushes it into the mill [6] The fan operates at high temperatures and must be designed to handle the dust Operational parameters affecting the vertical roller mill 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill

A review on current techniques used in India for rice mill wastewater

2021年1月4日 The rice mill wastewater has a high concentration and wide range of organic matter, total dissolved solids, phenol and nutrients (Table 2)The huge variation in pH and organic matter concentrations depend upon the paddy characteristics, milling process and quality and quantity of water used for parboiling (Kumar et al 2016a)The effluent Quality control of paper manufacturing is a process of ensuring that the paper products produced by a paper mill meet the quality standards specified by the customer It involves monitoring and verifying the quality of raw materials, process parameters, and finished products throughout the paper production processPaper Manufacturing Quality Control A Comprehensive 2018年12月10日 The raw mill considered in this study is located in a cement plant located in Gaziantep, Turkey The plant is a double chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 102 tons/h The mill diameter is 4000 mm and the grinding chamber length is 9,950 mm (Table 1)DETERMINATION OF CORRELATION BETWEEN SPECIFIC

Parametric Studies of Cement Production

2019年11月13日 The cement industry is one of the most intensive energy consumers in the industrial sectors The energy consumption represents 40% to 60% of production cost Additionally, the cement industry 2020年2月15日 The most important kiln controlling parameters are clinker production rate, fuel flow rate, specific heat consumption, secondary air temperature, kiln feedend temperature, preheater exhaust gas (PDF) Parametric Studies of Cement Production Processes2017年10月27日 of the raw material [1, 2] For VRM the production capacity denotes both the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table PROCESS CONTROL FOR CEMENT GRINDING IN

UDC 66476 DOI: 1015587/270654482022 RESEARCH

2023年10月7日 from similar raw materials in a roller mill – the most common design in service with mills Physical indicators of the powders, thermophysical properties and biotechnological parameters were 2023年7月22日 from similar raw materials in a roller mill – the most common design in service with mills Physical indicators of the powders, thermophysical properties and biotechnological parameters were UDC 66476 DOI: 1015587/270654482022 RESEARCH 2021年1月19日 Our paper presents the hammer mill working process optimization problem destined for milling energetic biomass (MiscanthusGiganteus and Salix Viminalis) For the study, functional and constructive parameters of the hammer mill were taken into consideration in order to reduce the specific energy consumption The energy Sustainability Free FullText Optimization Issues of a Hammer Mill

Modeling Vertical Roller Mill Raw Meal Residue by Implementing Neural

This study proposes a method for modeling the Vertical Roller Mill (VRM) to predict residue 90 micron and residue 200 micron of the raw meal product using Back Propagation Neural Network (BPNN) The modelling step is input preparation, Artificial Neural Network (ANN) structure determination, optimizer and loss function selection, training ANN and model 2021年6月29日 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement The research focuses on the mill speed as well as air classifier speed effect on the two (PDF) Effects of Mill Speed and Air Classifier Speed onContribute to changjiangsx/ development by creating an account on GitHub/ raw mill technical parametersmd at main