عنا

مرحبا هل يمكنني مساعدتك؟

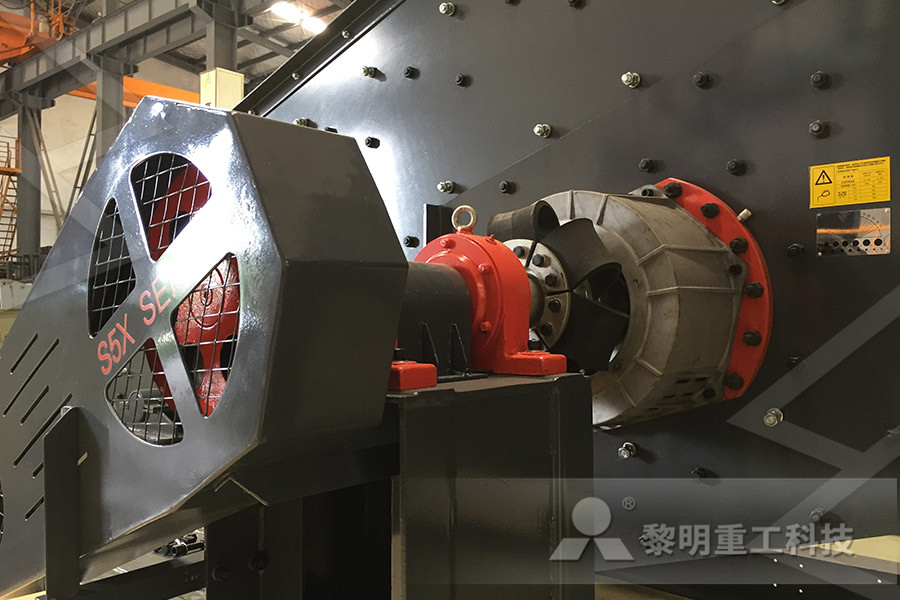

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Ball Mill grinding Media Glass Bead

2023-09-02T23:09:38+00:00

Glass Bead Media Glass Milling Media FOX Glass Grinding Balls

2023年11月5日 A FOX Glass grinding ball is, without a doubt, the best glass milling media in the world It’s like getting the power of a jackhammer applied with the gentleness of a 1 天前 From Albania to Zimbabwe, and everywhere in between, FOX grinding beads are used as milling media for the ultrafine grinding of Coatings, Paints, Inks, Pigments, Milling Media Ball Mill Grinding Media FOX Industries2023年4月23日 The motion of grinding media in a ball mill is essential since it has a grea t impact on the breakage of ore parti cles When the mill speed increa ses, the charge motion changes from sliding to (PDF) Grinding Media in Ball MillsA Review

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 Although there are several types of grinding media, which include inert grinding media such as ceramic, zirconia, agate, and glass, this section is going to focus Grinding Media Ball Bead 7,142 products found from 148 Grinding Media Ball Bead manufacturers suppliers Product List ; Supplier List; View:China Grinding Media Ball Bead, Grinding Media Ball Bead 2023年11月3日 Elevate your grinding performance with Allwin Grinding's premium grinding media Precision, durability, and quality for unmatched results Explore now ⮞Grinding Media Balls — Price for Milling Beads

China Grinding Ball Media Bead, Grinding Ball Media Bead

China Grinding Ball Media Bead manufacturers Select 2023 high quality Grinding Ball Media Bead products in best price from certified Chinese 4 Grinding Wheel, Abrasive Ball Mill Grinding Bead 7,207 products found from 141 Ball Mill Grinding Bead manufacturers suppliers Product List ; Supplier List; View:MadeinChinaChina Glass Grinding Ball manufacturers Select 2023 high quality Glass Grinding Ball products in best price from certified Chinese Grinding Tool, Grinding Polishing suppliers, China Glass Grinding Ball, Glass Grinding Ball Manufacturers,

Bead Mill Vs Ball Mill

2022年8月30日 Bead Mill: The grinding media of the bead mill generally uses zirconia beads, zirconium silicate beads or glass beads, which are selected according to different abrasive materials used by different manufacturers ELE Bead mill adopt high wearresistant alloy steel as the grinding material, its hardness can reach HRC62, so our company bead 2023年9月4日 Glass beads have replaced the conventional grinding media : Ottawa sand, Steel balls, Pebbles, Ceramic balls etc in Sand mills, Ball mills, Attrition mills for the following simple reasons : They are free from impurities, clean and easily cleanedGrinding Media, Dispersing Media, Grinding Media Glass Beads 2023年11月2日 NETZSCHBeads® Grinding Media These interactions enable a range of processes Depending on the particular product and task at hand, these could include size reduction, dispersion, or deagglomeration processes, as well as emulsification, cell disruption, or homogenization As the tools of the ball mill, the media have a crucial Grinding Media, Grinding Balls NETZSCH Grinding

Bead Mills Grinding and Dispersing Group

With over 90 years of experience, we have established a profound expertise and a broad customer base in almost every application in the wet grinding and dispersing industry From fullvolume up to highenergy bead mills, we set the technology standards for efficient, sustainable wet grinding processes2023年7月10日 Glass, ceramic and steel balls, zirconium, and river sand have all been utilised as grinding mediums in stirred mills Kwade, A; Blecher, L; Schwedes, J Motion and stress intensity of grinding beads in a stirred media mill Part 2: Stress intensity and its effect on comminution Powder Technol 1996, 86, 69–76 [Google Scholar]EnergyEfficient Advanced Ultrafine Grinding of Particles 2012年6月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the Effect of the size of media on grinding performance in stirred mills

Effect of ball and feed particle size distribution on the milling

2018年6月1日 The ball mill, liners and grinding media employed were made from stainless steel This material of construction is superior over all else because of its durability and resistance to wear and tear It is due to these reasons that contamination of the material was ruled out Experimental validation on the absence of contamination through 2022年3月30日 Ceramic Beads Balls Fine Grinding Media; Ceramic Shots for Blast Cleaning Microblast; Coating Equipment The nature of the ball mill (hardness of grinding material) recycling, metallurgy, glass, ceramics, or areas where pellets are required in powdered form Related Posts 2022 Best Materials Engineering Graduate Introduction to HighEnergy Ball Mill: Working Principle, 2020年11月2日 Yttria stabilized Zirconia (YSZ) media for planetary and roller ball mills YSZ is one of the most universal ceramic milling medias It is very corrosion resistant, very wear resistant, hard, stable in acid solutions, and because of these properties they are essentially noncontaminating to your sample Density: 61 g/cm 3Milling Media: Factors for choosing milling media for planetary

The effect of media type on regrinding with stirred mills

2005年1月1日 Media type (steel shot, glass beads, alumina balls and crushed quartz), media size, mill speed and the number of passes required to obtained the target product size are studied2013年12月1日 1 Introduction Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry [1], [2], [3]The ball mill process is very complicated process governed by many parameters, such as ball size, ball shape, ball filling, slurry loading (with respect to ball amount), powder Effect of ball size and powder loading on the milling efficiency 2011年2月1日 Research Highlights The effect of mill media material properties on grinding efficiency, media wear, and power consumption was defined High density media with optimum sizing improved milling efficiency by approximately 30% Mill media with a low coefficient of friction resulted in reduced energy consumption of up to 23 times in the Effect of media size and mechanical properties on milling

Grinding Efficiency Between Bead Mill and Ball Mill LinkedIn

2023年9月5日 Bead Mill vs Ball Mill Many researchers have conducted extensive experiments on the grinding efficiency of ball mills and bead mills, and the results show that bead mills are far superior to 2023年9月4日 Mills of sealed type should not be overloaded lest the machine and the beads are damaged Mills of open type should be optimally loaded with the beads In case of unsmooth running, reduce the bead charge gradually The bead charge shall be 8085% for sealed horizontal, 7080% for sealed vertical, and 6075% for open types Mills Bead Size Grinding Media Stanford Materials1 General knowledge of bead mill The bead mill is an apparatus that agitates grinding media (beads) in a cylindrical vessel to grind or disperse minute particles in slurry The rotor of the mill generates bead motion, which induces intense shear force and impact on the particles The bead mill is applied to a wide range of applications, such Bead Mill, Principle and Applications / Apex Mill series

Lab Mills Grinding Mills, Jar Mills, Accessories ColeParmer

1 天前 Lab mills for grinding, pulverizing, chopping samples for routine analysis ColeParmer® Grinding Balls for HighEnergy Mixer/Mill® Grinding Vial Sets $980 $13900 USD / Pkg of 100 View All 16 BioSpec Products MiniBeadBeater Glass Mill Beads, 05 mm; 1 lb EW3627051 $8200 USD / Pound of 1 Add To CartWe are a leading Importer of 92% High Alumina Ceramic Grinding Balls, Transparent Glass Beads (Grinding Purpose), Zirconium Silicate Beads, Ceramic Balls (For Bead Mills, Attritor Ball Mills ) and Steel Grinding Media from Morbi, India 92% High Alumina Ceramic Grinding Balls ₹ 120/ Kg Transparent Glass Beads (Grinding Purpose)Grinding Media 92% High Alumina Ceramic Grinding Balls 2007年12月31日 The stress model was developed to better describe the energy transfer from the grinding beads to the material to be ground and is applicable to planetary ball mills as well as stirred media mills Chapter 6 Wet Grinding in Stirred Media Mills Request PDF

Effect of Grinding Media Size on Ferronickel Slag Ball Milling

2021年12月27日 The aim of this study is to evaluate the effect that the size of grinding media exerts on ferronickel slag milling efficiency and energy savings A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizes In order to simulate the 2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeBall Mills 911 Metallurgist2020年10月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the Evolution of grinding energy and particle size during dry ball

Ceramic bead behavior in ultra fine grinding mills

2016年11月1日 SaintGobain Zirpro has been instrumental in the development of ceramic media for ultrafine grinding applications in stirred mills The history and experience are long, dating back to the mid nineteen seventies The company was infact established in 1971 to refine Zirconium Oxide to meet the SaintGobain Glass requirements for high 2016年1月1日 The performance of grinding media in a ball mill is also measured in terms of its wear rate Abrasive ores such as gold and copper produce high wear rates of about 120µm/hr [74] (PDF) A comparison of wear rates of ball mill grinding mediaChina Zirconium Silicate Bead Grinding Media manufacturers Select 2023 high quality Zirconium Silicate Bead Grinding Media products in best price from certified Chinese Zirconium, Zirconium Products suppliers, wholesalers and factory on MadeinChina High Density Low Wear Loss Milling Beads Zirconium Silicate Grinding Media Ball for China Zirconium Silicate Bead Grinding Media, Zirconium Silicate Bead

Grinding Bead at Thomas Scientific

Bertin Corp Hard tissue grinding MK28R 28mm metal beads 2mL pre filled Reinforced tubes ; Reinforced Lysing kit for Precellys MK28R Hard tissue kit 2mL tubes 50 prep The MK28 matrix is composed of 28mm Metal beads recommended for hard tissues such as muscle, skin, spinal cord, bone, teeth, hair but Compare this itemMany facets of grinding media can be customized, such as: STR Industries is a professional ball manufacturer and we have been manufacturing media for 30 years We are TS 16949 (auto industry standard, higher than ISO 9001) certified Our 200,000 square foot facilities produce more than 400 metric tons of balls per monthGrinding Media – STR Industries2021年9月1日 The grinding media fill consists of 4 mm steel balls, the feed rate is constant in all tests at 400 kg/h and only the circumferential speed has been varied in the range of 36 m/s (300 rpm) to 60 m/s (500 rpm) Motion and stress intensity of grinding beads in stirred media mill Part 1 and Part 2 Powder Technol, 86 (1996) Google Scholar Geometry influence on optimized operation of a dry agitator bead mill

Grinding Media Glen Mills, Inc

2023年10月28日 The grinding media is actually alumina particles held in place by an SiO2 glass phase Sizes from 400 microns to over 1 inch in beads, balls, satellites (ball with bands) and cylinders Low to medium cost, small sizes are more costly Fused Zirconium oxide Grinding Media (spgr 38) Smooth surface leads to low mill wear and longevity 2018年3月1日 The results showed that wet grinding in a stirred bead mill using the smaller grinding media (500 µm) is an effective method for reduction of product size (∼500 nm) of the CaCO3 powder Effect of Agitator Shaft Direction on Grinding Performance in Media 2018年7月1日 By using small grinding media in agitated ball mills the production rate can be increased, or at the same energy level smaller particles can be obtained by grinding or deagglomerationAssessing the influence of viscosity and milling bead size on

Analysis and Modelling of Bead Contacts in WetOperating Stirred Media

2015年6月1日 The interactions between slurry, grinding media and mill structure are modelled by twoway couplings between the PFEM, the DEM and the FEM models out using 3mm glass bead particles at a mass 2016年7月1日 The grinding media may be the ore itself (autogenous grinding), bars, balls, or cylpebs, or even the ore itself together with a small amount of balls (semiautogenous grinding) A survey found out that approximately 53% of the grinding circuits around the world use ball mills, and 38% use autogenous or semiautogenous grinding, and A discussion on the measurement of grinding media wearBall Mill Grinding Bead 7,207 products found from 141 Ball Mill Grinding Bead manufacturers suppliers Product List ; Supplier List; View:MadeinChina

MadeinChina

You can expect to pay between 01 to 1101 for each Industrial Grinding Media Price The cost of a Industrial Grinding Media Price varies by the different parameters2021年10月18日 The breakage and liberation of minerals are the key to fluidized mining for minerals In the ball milling process, steel balls function as not only a grinding action implementer but also energy carrier to determine the breakage behavior of ores and the production capacity of the mill When ground products present a much coarse or much The Effect of Grinding Media on Mineral Breakage Properties Zirconia ball mill grinding media : 023mm,5mm,10mm,15mm,20mm Usage of the Zirconia ball mill grinding media: Ø053mm Grinding Compare this product Remove from comparison tool silicon nitride ballGrinding ball, Grinding bead All industrial manufacturers

China Milling Media Grinding Bead, Milling Media Grinding Bead

China Milling Media Grinding Bead wholesale Select 2023 high quality Milling Media Grinding Bead products in best price from certified Chinese Custom Glass Bead manufacturers, Fashion Bead Jewelry suppliers, wholesalers and factory on Madein MSE Supplies provides quality, durable, and highperformance milling media Milling balls made of steel and ceramic are our most popular materials If you have questions regarding MSE Supplies milling media, please request a quote, contact us online, or call us at (520)7896673 today Our inhouse experts are ready to help you select the best Milling Balls Grinding Media Grinding Balls MSE Supplies2022年8月30日 Bead Mill: The grinding media of the bead mill generally uses zirconia beads, zirconium silicate beads or glass beads, which are selected according to different abrasive materials used by different manufacturers ELE Bead mill adopt high wearresistant alloy steel as the grinding material, its hardness can reach HRC62, so our company bead Bead Mill Vs Ball Mill

Grinding Media, Dispersing Media, Grinding Media Glass Beads

2023年9月4日 Glass beads have replaced the conventional grinding media : Ottawa sand, Steel balls, Pebbles, Ceramic balls etc in Sand mills, Ball mills, Attrition mills for the following simple reasons : They are free from impurities, clean and easily cleaned2023年11月2日 NETZSCHBeads® Grinding Media These interactions enable a range of processes Depending on the particular product and task at hand, these could include size reduction, dispersion, or deagglomeration processes, as well as emulsification, cell disruption, or homogenization As the tools of the ball mill, the media have a crucial Grinding Media, Grinding Balls NETZSCH GrindingWith over 90 years of experience, we have established a profound expertise and a broad customer base in almost every application in the wet grinding and dispersing industry From fullvolume up to highenergy bead mills, we set the technology standards for efficient, sustainable wet grinding processesBead Mills Grinding and Dispersing Group

EnergyEfficient Advanced Ultrafine Grinding of Particles

2023年7月10日 Glass, ceramic and steel balls, zirconium, and river sand have all been utilised as grinding mediums in stirred mills Kwade, A; Blecher, L; Schwedes, J Motion and stress intensity of grinding beads in a stirred media mill Part 2: Stress intensity and its effect on comminution Powder Technol 1996, 86, 69–76 [Google Scholar]2012年6月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the Effect of the size of media on grinding performance in stirred mills 2018年6月1日 The ball mill, liners and grinding media employed were made from stainless steel This material of construction is superior over all else because of its durability and resistance to wear and tear It is due to these reasons that contamination of the material was ruled out Experimental validation on the absence of contamination through Effect of ball and feed particle size distribution on the milling

Introduction to HighEnergy Ball Mill: Working Principle,

2022年3月30日 Ceramic Beads Balls Fine Grinding Media; Ceramic Shots for Blast Cleaning Microblast; Coating Equipment The nature of the ball mill (hardness of grinding material) recycling, metallurgy, glass, ceramics, or areas where pellets are required in powdered form Related Posts 2022 Best Materials Engineering Graduate 2020年11月2日 Yttria stabilized Zirconia (YSZ) media for planetary and roller ball mills YSZ is one of the most universal ceramic milling medias It is very corrosion resistant, very wear resistant, hard, stable in acid solutions, and because of these properties they are essentially noncontaminating to your sample Density: 61 g/cm 3Milling Media: Factors for choosing milling media for planetary 2005年1月1日 Stirred ball mills are more advantageous especially in grinding 75 µm due to their easier operation, simpler construction, lower energy consumption and higher grinding rate compared to The effect of media type on regrinding with stirred mills