عنا

مرحبا هل يمكنني مساعدتك؟

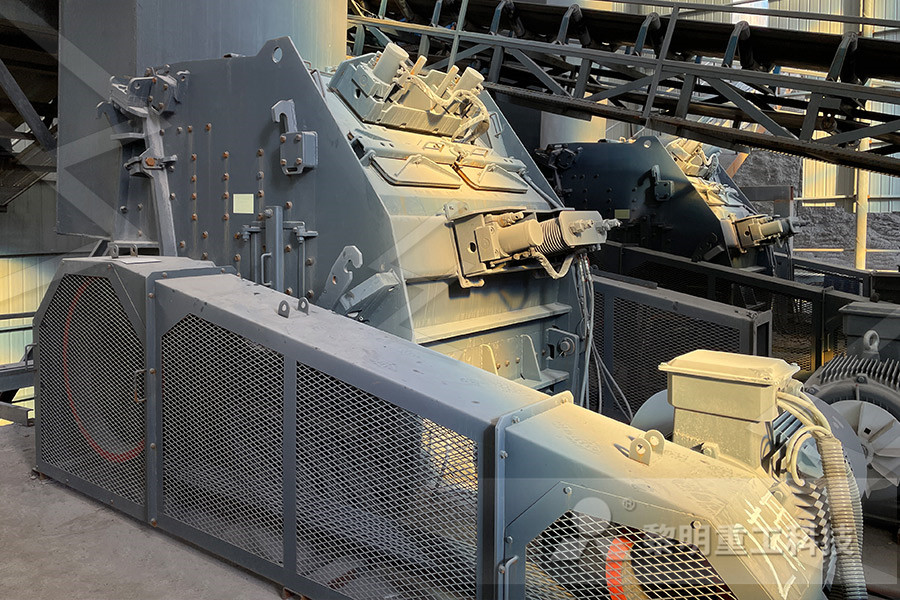

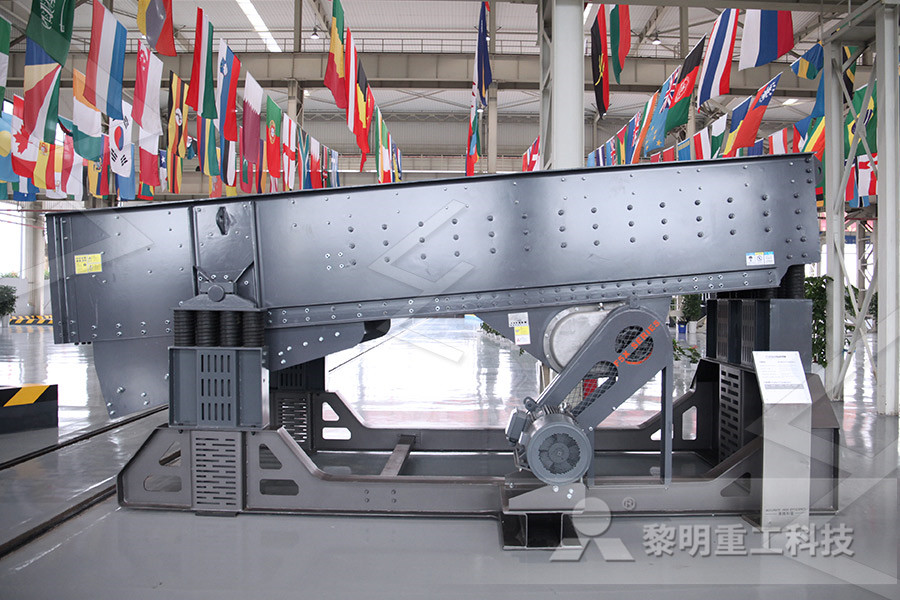

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

mineral crushing with high capacity

2021-06-12T04:06:13+00:00

Study on Impact Crushing Characteristics of

2023年4月30日 In order to quantitatively analyze the impact crushing characteristics of mineral components in ores, this paper takes pure mineral quartz, pyrrhotite, and pyrite as the research objects and uses the 2021年6月24日 all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due Crushing and Screening Handbook AusIMM2022年6月6日 Simulations indicated that a capacity increase of 12% would be achieved in the existing grinding circuit by further crushing 35% of SAG mill fresh feed Such figures would represent yearly additions of 83 kt in Minerals Free FullText PreProcessing to

Modeling and Improving the Efficiency of Crushing Equipment

2023年5月16日 The necessity to develop energyefficient technologies for the mineral industry will increase in the future, considering the exhaustion of highquality resources The highpressure water jet mineral dissociation technology is a new technology which is developed in response to these requirements The experiment shows that the water jet Research on the Increase of Mineral Dissociation Degree 2023年4月30日 Impact Crushing Characteristics of Minerals Based on Drop Weight Tests Minerals 2023, 13, 632https:// ment production and processing capacity directly affect 1,2, Hengjun Li 2 1 MDPI

Effects of compression and sliding on the wear and energy

2018年3月15日 The high energy consumption of crushing is one of the main motivations to study the comminution of minerals Tromans [1] listed several examples of energy 2021年11月6日 Samples of specific crushing products in a total mass about 200 kg each, were collected from the belt, after stabilization of the circuit capacity Next, they were subjected to a mass reduction with use Minerals Free FullText Optimization of 2019年2月5日 This publication summarizes some of the features and experiences for HPGR application in pebble crushing and includes a an example case study of pebble crushing in a copper minerals processing (PDF) PEBBLE CRUSHING BY HPGR ResearchGate

Crushing and Screening Handbook AusIMM

2021年6月24日 all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit all secondary, tertiary or quarternary crushing applications High performance 2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) minution and classification technologies of iron orePrimary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Crusher automation – ensures consistent and efficient operation Improves productivity and product quality while reducing maintenance costs by preventing overload situations This is where the Minerals Crushing and Screening Crushing And Screening Handbook Kevin Berrocal BaixarDoc

The Complete Guide to Primary Crushing, Secondary Crushing

2023年2月28日 This makes it ideal for use in highcapacity crushing plants However, primary crushing also has its disadvantages, including high energy consumption and the risk of overcrushing the material, which can lead to the formation of fines and result in a lowerquality end product Common Applications of Primary Crushing in the Aggregates Industry2009年5月1日 Predicting the overall specific energy requirement of crushing, high pressure grinding roll and tumbling mill circuits May 2009 Minerals Engineering 22(6):544549(PDF) Predicting the overall specific energy requirement of crushing 2021年7月27日 Crushing is one of the most energyconsuming technological processes The purpose of grinding is to achieve the desired grain size of mineral raw materials The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the Influence of Natural Aggregate Crushing Process on Crushing

Mineral Crushing Methods for Noble Gas Analyses of Fluid

2023年6月14日 Noble gases are frequently probed for investigating fluid inclusions in minerals to unravel rockforming processes through time Over the last decades, heating and crushing have been the two main methods applied for noble gas extraction from fluid inclusions in ultrahigh vacuum (about 109 mBar) The heating of minerals 2021年9月10日 High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breaking However, there is currently a lack of detailed understanding of the microwave parameters regarding magnetite ore The purpose of this study is to fully understand the potential Minerals Free FullText Study on Magnetite Ore Crushing VSI crusher RSMX series stationary sand production Capacity: 30 t/h 500 t/h Motor power: 160 kW 400 kW Weight: 7,500 kg 20,200 kg The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materialsSand production crusher, Sand production crushing plant

Modelling and simulation of dynamic crushing plant

2013年4月1日 Crushing performance and the effects of wear on cone crusher have been described in detail by Evertsson (2000) and Lindqvist (2005) Due to wear the geometry of the liner will change gradually during the lifetime of the liners, causing changes in crusher capacity and particle size distribution of the crushed material2023年4月30日 Impact Crushing Characteristics of Minerals Based on Drop Weight Tests Minerals 2023, 13, 632https:// ment production and processing capacity directly affect and limit the scale efficiency of the concentrator More importantly, the crushing operation is the material preparation stage for Many mineral resources of high grade that are 1,2, Hengjun Li 2 1 MDPI2018年3月15日 1 Introduction The high energy consumption of crushing is one of the main motivations to study the comminution of minerals Tromans [1] listed several examples of energy consumption per country, showing that the energy spent in comminution constituted 1–167% of the total energy consumed by the industry The exact value Effects of compression and sliding on the wear and energy

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 Crushing capacity • with primary screening • high fines content CSS jaw opening [mm] EB 1210 H EB 1411 H EB 1612 H EB 2015 H Average throughput rate of singletoggle jaw crusher, hardrock version, tolerance ± 10% 100 150 swing jaw moves forward Serrated jaw plates enhance the crushing process When the 200 250 300 350 2021年10月14日 High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breaking However, there is currently a lack of detailed understanding of the microwave parameters regarding magnetite ore The purpose of this study is to fully understand the potential Minerals Free FullText Study on Magnetite Ore Crushing 2021年11月6日 The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products Qualitative characteristics of crushing products in terms of size reduction ratio and fine particles contents were analyzed from the point of view of operational parameters of the impact Minerals Free FullText Optimization of Aggregate

Minerals Free FullText Constant Wear Criterion for

2022年5月20日 Cone crushers are highefficiency particle crushing instruments utilized in a variety of industries []The crushing chamber is one of the core components of a cone crusher [], and is directly related to the performance of the cone crusher and the quality of the crushed productsMeanwhile, changes in the crushing chamber caused by wear can 2020年12月17日 Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each otherCrushing 101 – Different types of crushers for distinctive needs2015年12月26日 Crushing in Mineral Processing crushing Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911 Metallurgist

Five Types of Crusher in the Mineral Processing LinkedIn

2020年9月16日 The crushing cavity of jaw crushers is deep without dead zone, so the feeding capacity and production of this type of crusher have been greatly increased, featured by large reduction ratio and 2022年6月2日 material crushing is used in the treatment of raw materials and catalysts 2 Mineral dissociation technology 21 Mineral dissociation technology by ball mill At present, as the main crushing equipment, ball mill is widely used in the processing and metallurgy of metal and nonmetal ores, as well as the crushing part of some basicResearch on the Increase of Mineral Dissociation Degree 2021年11月1日 In summary, the highstress, hightemperature, and highwaterpressure environment of deep rock masses determines the original physical and mechanical characteristics of the rock masses, and Peng LI, Meifeng CAI/Trans Nonferrous Met Soc China 31(2021) 3478−3505 3482 the strong engineering disturbance induced by deep Challenges and new insights for exploitation of deep underground metal

(PDF) Research on the Increase of Mineral Dissociation Degree by High

2021年1月1日 The highpressure water jet mineral dissociation technology is a new technology which is developed in response to these requirements The experiment shows that the water jet technology has a 2 天之前 Capacity, MTPH performance figures are approximate and give an indication of what the crusher can produce They apply to open circuit crushing of dry materials with a bulk density of 1600kg/m3 It is assumed that material much finer than the crusher’s closed side setting (CSS) is removed from the feedHydraulic Cone Crusher AF Minerals Equipmentand the subsequent required recrushing of these results in an extra burden for the (S)AG mill in the form of a recirculating load of harder and more abrasive material HPGRs are high capacity crushing units providing a high reduction ratio, especially in terms of the generation of finer particle size fractions than conventional crushersPEBBLE CRUSHING BY HPGR FP van der Meer Weir

(PDF) Review of the inpit crushing and conveying (IPCC

2011年10月24日 The large iniit crushing, continuous haulage and spreading system with high capacity for overburden was commissioned in 1984 in the openpit mine Mae Moh of the Thai Electricity Commission EGAT Contribute to dihog/ development by creating an account on GitHub/ capacity crushing plantmd at main dihog/2023年4月30日 The degree of difficulty in crushing an ore depends on the composition of the ore itself Due to different types and compositions of ores, the crushing mechanism of ores during the crushing process is also different In order to quantitatively analyze the impact crushing characteristics of mineral components in ores, this paper takes pure Minerals Free FullText Study on Impact Crushing MDPI

Research on the Increase of Mineral Dissociation Degree

with high efficiency and low price for the development and resource utilization of ultrafine grinding industry in China 3 Mineral dissociation device by high pressure water jet This experiment uses a selfdeveloped highpressure water jet mineral crushing device, which is mainly composed of power device, crushing device and separation device2018年11月19日 Abstract and Figures The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of treating crude material from (PDF) Comminution in mineral processing ResearchGate2016年1月1日 To perform the operation, pressure is applied hydraulically through four cylinders to the roll that is designed to move laterally The second roll is immovable A crushing pressure of the order of 200 MPa is applied The dimensions of the rolls used in the mineral industry are [5] 07− 28 m diameter with a length/diameter ratio between 02 Roll Crushers ScienceDirect

(PDF) ENERGY EFFICIENCY IN COMMINUTION GETTING MORE FROM THE CRUSHING

2020年1月13日 Crushers CH860 CH865: G etting More in Crushing Ores, Proceedings of Minerals Engineering IMPC 2016: XXVIII International Mineral Processing Congress Proceedings ISBN: 9781292 Page 2023年4月30日 The crushing operation of ores is widely used in solid mineral resource processing fields such as mining, the chemical industry, metallurgy, building materials, thermal power, etc [1,2,3]The crushing process of ore plays a very important role in mineral processing production, with its infrastructure costs accounting for about 60% of the Minerals Free FullText Study on Impact Crushing MDPI2017年3月3日 Particle impact noise detection (PIND) test is a kind of reliability screening technique which is used to detect free particle in hermetical components and is specified in MILSTD883E method 20207(PDF) ORE SEPARATION BY SCREENING ResearchGate

Minerals Free FullText Study on Impact Crushing MDPI

2023年4月30日 The crushing operation of ores is widely used in solid mineral resource processing fields such as mining, the chemical industry, metallurgy, building materials, thermal power, etc [1,2,3]The crushing process of ore plays a very important role in mineral processing production, with its infrastructure costs accounting for about 60% of the 2017年3月4日 The process Comminution involves size reduction and sizewise classification called as screening/ separation Milling is one of the most important industrial processes The electric power (PDF) SIZE REDUCTION BY GRINDING METHODS2022年10月21日 Cone Crusher: Application Material Capacity Factors October 21, 2022 A cone crusher is a kind of medium and fine crushing equipment, which is mainly used to produce stone size, and its discharge particle size is less than 5 cm It can process 05mm, 510mm, 1020mm, and 2040mm four kinds of stones Hard rock is a material Cone Crusher: Application Material Capacity Factors JXSC Mineral

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the 2023年7月1日 Heating and mechanical crushing are the two most common approaches to extracting fluid inclusions from mineral grains for noble gas analysis Less common is the extraction of noble gases by laser ablation In comparison to heating, crushing is less efficient in breaking all fluid inclusions [43] Heating of whole rock or mineral samples is Mineral Crushing Methods for Noble Gas Analyses of 英语网站资料 Contribute to boy/en development by creating an account on GitHuben/crushing on mineral processmd at main boy/en

Crushing and Screening Handbook AusIMM

2021年6月24日 all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit all secondary, tertiary or quarternary crushing applications High performance 2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) minution and classification technologies of iron orePrimary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Crusher automation – ensures consistent and efficient operation Improves productivity and product quality while reducing maintenance costs by preventing overload situations This is where the Minerals Crushing and Screening Crushing And Screening Handbook Kevin Berrocal BaixarDoc

The Complete Guide to Primary Crushing, Secondary Crushing

2023年2月28日 This makes it ideal for use in highcapacity crushing plants However, primary crushing also has its disadvantages, including high energy consumption and the risk of overcrushing the material, which can lead to the formation of fines and result in a lowerquality end product Common Applications of Primary Crushing in the Aggregates Industry2009年5月1日 Predicting the overall specific energy requirement of crushing, high pressure grinding roll and tumbling mill circuits May 2009 Minerals Engineering 22(6):544549(PDF) Predicting the overall specific energy requirement of crushing 2021年7月27日 Crushing is one of the most energyconsuming technological processes The purpose of grinding is to achieve the desired grain size of mineral raw materials The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the Influence of Natural Aggregate Crushing Process on Crushing

Mineral Crushing Methods for Noble Gas Analyses of Fluid

2023年6月14日 Noble gases are frequently probed for investigating fluid inclusions in minerals to unravel rockforming processes through time Over the last decades, heating and crushing have been the two main methods applied for noble gas extraction from fluid inclusions in ultrahigh vacuum (about 10 9 mBar) The heating of minerals or pieces of 2021年9月10日 High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breaking However, there is currently a lack of detailed understanding of the microwave parameters regarding magnetite ore The purpose of this study is to fully understand the potential Minerals Free FullText Study on Magnetite Ore Crushing VSI crusher RSMX series stationary sand production Capacity: 30 t/h 500 t/h Motor power: 160 kW 400 kW Weight: 7,500 kg 20,200 kg The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materialsSand production crusher, Sand production crushing plant