عنا

مرحبا هل يمكنني مساعدتك؟

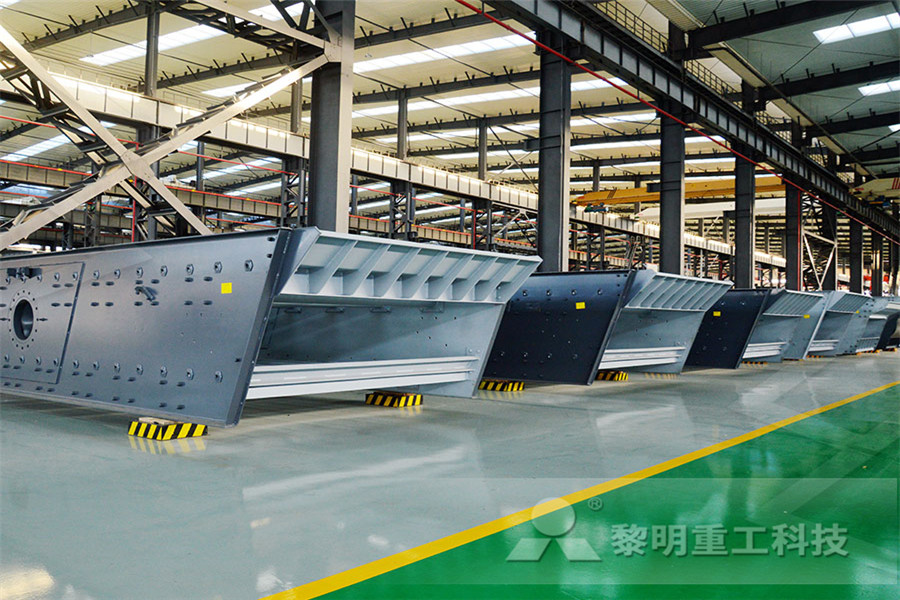

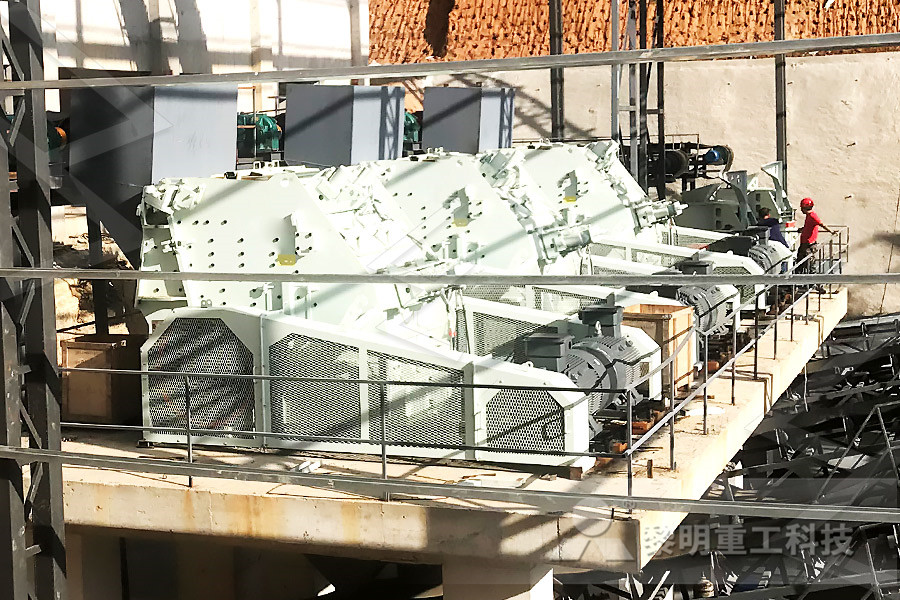

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

cyanidation process for dressing of ore high quality

2022-04-13T18:04:18+00:00

5 Improvements to the cyanidation process for precious

2018年1月1日 Principles of the cyanidation process in the mining industry Cyanidation is a leaching process widely applied in precious metal recovery This hydrometallurgical procedure has been used for several decades due to its effectiveness in dissolving 2020年5月21日 Abstract Globally, copper, silver, and gold orebody grades have been dropping, and the mineralogy surrounding them has become Metals Free FullText A Review of the 2023年8月21日 This article includes the application of roasting pretreatment by assisting the cyanidation process in the recovery of Au–Ag from Bolkardağ Gossan refractory ore The Effect of Roasting on the Mineralogical Structure and Cyanidation

Optimizing and evaluating the operational factors

2015年12月8日 The cyanidation process is affected by a number of influential parameters, such as the availability of oxygen at the 2020年6月27日 Citation: Alizadeh M, Alizadeh M, Salehi A, Mohammadi M Improving The cyanidation process of gold ore containing sul de compounds by water treatment and (PDF) Improving the cyanidation process of gold ore2013年7月11日 A key operation in the cyanide leaching circuit proposed is a SART process (Sulphidization, Acidification, Recycling and Thickening), which is being used presently at many gold plants to recover(PDF) Cyanide Leaching of CopperGoldSilver

Cyanidation of gold ores containing copper, silver, lead, arsenic

2010年7月1日 1 Introduction 11 General Early studies on the dissolution of gold in cyanide solution in the presence of sulfide minerals have shown that heavy metal 1998年6月1日 The truth about cyanidation process and its environmental effects on gold mining Ore and products after pretreatmen t come (10 g in 50 mL of deionized water) were 344 and 1611 mScm1 (PDF) The truth about cyanidation process and its 2010年1月1日 Cyanide leaching is currently the dominant process used by the minerals industry to extract gold (and silver ) from geological ores Gold extraction is Cyanidation Wastes of GoldSilver Ores SpringerLink

Leaching of finely disseminated gold ore with cyanide and

2003年4月1日 In this study, the aim was to investigate the gold recovery from finely disseminated ore by using thiourea as an alternative to the cyanidation process 2022年5月26日 In recent years, the demand for lithium ore resources has been increasing, and the technology of lithium extraction has also been developed rapidly Method #1: Lithium Flotation Process Method #2: Ultimate Guide: 6 Methods for Lithium Extraction2020年5月21日 The cyanidation process for gold production has remained dominant for over 130 years because of its selectivity and feasibility in the mining industry Plenge, G Estimating Process Design Gold Metals Free FullText A Review of the

Common processes in gold ore dressing production

2021年6月15日 1Single flotation flowsheet this flowsheet is used to treat sulfide gold bearing quartz vein ore, polymetallic gold bearing sulfide ore and carbon (graphite) ore with fine gold particles and high floatability 2006年12月31日 temperatures, and high ore surface areas [15, 31] Although gold dissolution with chlorine is substantially faster than with cyanide, low concentrations of sulphides or other reactive(PDF) Alternatives to cyanide in the gold mining industry: 2022年2月1日 Most of the gold is encapsulated in sulfides and arsenopyrite in Carlin type gold concentrate; the gold leaching efficiency is less than 8% without pretreatmentCyanide process is a traditional gold leaching method with the disadvantages of several environmental pollution incidents occurred due the breach of tailings disposal In view of Extraction of gold from typical Carlin gold concentrate by

Treatment of copperrich gold ore by cyanide leaching,

2015年2月1日 Preaeration of ore prior to cyanidation and/or addition of lead nitrate can be beneficial for mitigating problems associated with sulphide minerals during cyanidation of gold [13,14,16] ammonia leaching as a pretreament process ahead of cyanidation was examined Meanwhile, direct cyanide leaching of gold at elevated levels of cyanide was 2020年6月9日 Now, we’re going to talk about the factors affecting gold vat leaching process 1 Cyanide Selection The main cyanides that can be used for gold vat leaching process include: KCN、NaCN、NH4CN 4 Factors Affecting Gold VAT Leaching Process LinkedIn2005年1月1日 Fig 7 illustrates the benefits of using a high oxygen content in cyanidation of a gold ore with low pyrite and pyrrhotite content (Deschênes et al, 1999) A 16 ppm oxygen concentration in leaching can result in a faster dissolution rate than a 147% increase in the cyanide concentration The use of oxygen has resulted in a 30% reduction in Advances in the cyanidation of gold ScienceDirect

Cyanidation of gold ores containing copper, silver, lead, arsenic

2010年7月1日 Cyanidation tests on two ore samples from two different gold deposits are reported The first sample contained 105 ppm gold with high arsenic and antimony The second sample had a low gold content (25 ppm) but a high silver content (160 ppm)The first series of test work focused on the determination of conditions for extracting gold 2020年11月13日 I Gold Ore Dressing Equipment for Cyanidation 1Zinc Powder Replacement Device The usage of zinc powder/wire to replace gold, is called cyanidezinc replacement process (CCD method and CCF method)Main Equipment for Gold Ore Dressing LinkedIn2023年3月10日 Artisanal and smallscale gold mining (ASGM) is present in over 80 countries, employing about 15 million miners and serving as source of livelihood for millions more The sector is estimated to be the largest emitter of mercury globally The Minamata Convention on Mercury seeks to reduce and, where feasible, eliminate mercury use in Mercury and artisanal and smallscale gold mining: Review

(PDF) Metals Special Issue: A Review of the

2020年7月5日 The investigations of direct cyanidation elucidated that the ore can consume a high amount of cyanide with unsatisfactory recoveries for gold (Exgold ≤3941%)2022年4月21日 It was found that the ore is favorable for its processing by the method of agitational cyanidation: the extraction of gold into a solution for a size of 95–0074 mm is 9356–9399% The following materials were used to study the sorption parameters: Norit RO 3515, Chemviron GAC 6065, Chemviron 205GR 6 × 12, Chemviron 207GR 6 × 12 Hydrometallurgical Processing of Gold Ore SpringerLink2013年7月11日 The high copper content in the ore forced the inclusion of a SART (sulphidisation, acidification, recycling and thickening) plant in the design of the cyanidation process to treat part of the (PDF) Cyanide Leaching of CopperGoldSilver Ores

Leaching of finely disseminated gold ore with cyanide and

2003年4月1日 The ore samples were taken from the GümüşhaneMastra gold deposit (situated in the East Blacksea Region of Turkey) in an amount of about 25–30 tons for pilotscale gold recovery experiments carried out by the cyanide leaching process These samples contain 125 g/ton Au and 152 g/ton Ag and a high percentage of SiO 2 (>90%)2019年10月29日 At present, the most commonly used gold extraction method is gold cyanidation More than 80% of the gold mines use gold cyanidation method to extract gold What are the methods for gold cyanidation?Summary of Gold Cyanidation Methods LinkedIn2018年3月1日 The cyanidation plants that include a MerrillCrowe (MC) process and present cyanidesoluble copper in the ore will have zinc and copper concentration in the cyanide solution In this regard, a SART process can be implemented, although the precipitate generated will be a mixture of ZnS and Cu 2 S losing saleable value as Designing the SART process – A review ScienceDirect

Lead Oxide Enhances the Leaching of Gold in Cyanide Tailings

2022年12月29日 Cyanidation tailings often contain a certain amount of gold, which is difficult to recover due to the influence of associated minerals In this article, lead oxide was used to increase leaching efficiency and decrease sodium cyanide consumption The mechanism of lead oxideenhanced gold leaching was studied by thermodynamic Al Amar gold ore is rich in sulfides of base metals and is commercially applied for the production of copper concentrate via floatation and gold bullion by cyanidation of tailing The current process flowsheet suffers from low gold recovery (∼60%) and loss of metals in the hazardous stockpiled residue This work addresses these drawbacks by a newly Developed Process Circuit Flowsheet of Al Amar Ore for 2015年8月1日 In this study, cyanidation experiments were carried out on a massive sulfide ore sample, whose grades of the precious metals gold and silver were found to be 42 g/t and 3119 g/t, respectively Other elements in the ore were arsenic with average grade of 1,7516g/t; antimony, 6197 g/t; zinc, 7814 g/t; copper, 4546 g/t; lead, 1018 g/t; Direct cyanidation and roasting combination of a semi

How to Reduce Sodium Cyanide Consumption of

2020年9月4日 2 Strictly Control the Copper Grade of Raw Ore Copper consumes a large proportion of cyanide in the leaching process For example, a gold cyanidation plant has a copper grade of 0548% in raw 2016年1月1日 Figure 267 illustrates the benefits of using a high oxygen content in cyanidation of a gold ore with low pyrite and pyrrhotite content (Deschênes et al, 1999) A 16 ppm oxygen concentration in leaching can result in a faster dissolution rate than a 147% increase in the cyanide concentration The use of oxygen has resulted in a 30% reduction Advances in the Cyanidation of Gold ScienceDirect2016年6月8日 Cyanidation The gold cyanidation process is the most important method ever developed for extracting gold from its ores The reasons the widespread acceptance of cyanidation are economic as well Cyanidation 911 Metallurgist

First application of cyanidation process in Turkish gold

2002年9月1日 In the Ovacik cyanidation plant, ore is first crushed and then wet ground in mills to liberate gold particles Once ground to −38 μm, a high degree of liberation hence recovery of gold from the ore is achieved 21 Cyanidation processApproximately 25 million tons of cyanide is manufactured annually worldwide2005年1月1日 1 Background For the past 100 years the key element in the processing of gold ore has been the cyanidation process Over the years steady improvements have occurred in equipment design; milling has evolved from stamp mills, through tube mills and ball mills to the large semiautogenous grinding (SAG) and fullyautogenous grinding Metallurgical testwork: Gold processing options, physical ore Contribute to yunan88/crusher development by creating an account on GitHubcrusher/ high performance leaching and adsorption for gold ore

Optimizing the alkaline oxidation pretreatment of a refractory gold ore

2018年9月28日 Res Express 101088/20531591/aae196 This study investigates the alkaline oxidation pretreatment process of Zarshuran refractory gold ore Taguchi methodorthogonal array design (OAD) is applied to evaluate and optimize the influence of five main factors including solution pH, aeration rate, agitation speed, temperature, and oxidation 2023年4月16日 Arsenious and sulphurbearing microdisseminated gold ore is a kind of typical refractory CarlinType The gold in CarlinType gold ore grains is distributed finely, existing as invisible or submicroscopic gold, encapsulated in arsenopyrite and pyrite The technical difficulty of treatment CarlinType gold ore lies in how to release the fine gold Minerals Free FullText Mineral Phase Evolution during2020年2月28日 With the increase in gold demand and the largescale mining of gold, gold with high grade and quality as well as easy access to exploit is decreasing, the proportion of refractory gold ore is larger than ever before Statistics show that the proportion of refractory gold ore is as high as 60% 70% of the total reserves in the world’s gold oreLeaching Guide of Refractory Gold Ore cnlitereagent

Development of a Sustainable Alternative for the Ammoniacal Cyanidation

2020年12月9日 Abstract Due to the problems arising from the presence of copper in the gold cyanidation process, including high cyanide consumption and occupation of the activated carbon surface, biological ammoniacal cyanidation was implemented as a resolution Bacillus megaterium was implemented to produce cyanide and ammonia in 2010年1月1日 51 Introduction Cyanide is a general term which refers to a group of chemicals whereby carbon and nitrogen combine to form compounds (CN – ) Cyanide leaching is currently the dominant process used by the minerals industry to extract gold (and silver ) from geological ores Gold extraction is accomplished through the selective Cyanidation Wastes of GoldSilver Ores SpringerLink2020年6月15日 A laboratoryscale process, including two different gravity separation steps (Knelson and Falcon centrifugal concentrators) followed by a series of varying intensity wet drum magnetic separation steps and dryinduced roll magnetic separation and wet high intensity magnetic separation steps, to beneficiate a rare earth ore was investigatedResearch and application of a Knelson concentrator: A review

Effectiveness acidic precleaning for coppergold ore

The objective was to evaluate the amount of soluble copper in cyanide before and after acidic cleaning From a gold ore containing copper, the study selected four samples containing 022%, 055%, 100% and 136% of copper For direct cyanidation of the ore without pretreatment, copper extraction by cyanide complexing ranged from 8 to 83%2019年2月27日 Cyanidation Methods Heap leaching Pool Leaching CIP CIL Application Low grade gold and silver ore and tailings Low grade gold and silver ore and tailings, low clay content Ore with deep oxidation and no copper tin and carbonaceous material Low sulfur content and high mud content Gold mine Recovery Rate 65~80% Summary of Gold Cyanidation Methods Miningpedia2022年7月31日 cyanidation process cy cle can be expedited by using preoxidation methods, it is still a lengthy process Ge nerally, leach ing refractory ores for 24 h or longer(PDF) Oxygen Potentials, Limitations and Enhancement

What is Iron Ore Treatment? Miningpedia

2022年10月25日 1 Single Magnetite Ore Beneficiation Process Single magnetite ore is often selected by weak magnetic separation method For large and mediumsized magnetic separation plant, when the grinding size is greater than 02 mm, a section of the mill magnetic separation is often used; less than 02 mm, two sections of the mill magnetic 2020年5月21日 The cyanidation process for gold production has remained dominant for over 130 years because of its selectivity and feasibility in the mining industry Plenge, G Estimating Process Design Gold Extraction, Leach Residence Time and Cyanide Consumption for High CyanideConsuming Gold Ore Miner Metall Process 2015, 32, Metals Free FullText A Review of the Cyanidation 2015年2月28日 In the cyanide leaching tests, those performed at a high cyanide level (ie, 5 g/L) produced high gold and silver extractions from the roasted ore apparently due to the increased availability of Treatment of copperrich gold ore by cyanide leaching,

The effects of dissolved oxygen and cyanide dosage on

2004年2月1日 The results of cyanidation of a preoxidized pyrrhotiterich gold ore in laboratory leaching experiments and in plant trials are presented to highlight the effects of particle size, oxygen and 2022年2月11日 The raw ore is in gravity separation process first, and the concentrate obtained from that is subjected to cyanidation to extract gold; or the raw ore is directly subjected to gravity separation, and then the tailings and graded ore are separately cyanidized ② Gravity separationFlotation combined process This gold ore How to Extract Gold From Ore? Mining Pedia2022年5月26日 In recent years, the demand for lithium ore resources has been increasing, and the technology of lithium extraction has also been developed rapidly Method #1: Lithium Flotation Process Method #2: Ultimate Guide: 6 Methods for Lithium Extraction

Metals Free FullText A Review of the

2020年5月21日 The cyanidation process for gold production has remained dominant for over 130 years because of its selectivity and feasibility in the mining industry Plenge, G Estimating Process Design Gold 2021年6月15日 1Single flotation flowsheet this flowsheet is used to treat sulfide gold bearing quartz vein ore, polymetallic gold bearing sulfide ore and carbon (graphite) ore with fine gold particles and high floatability Common processes in gold ore dressing production2006年12月31日 temperatures, and high ore surface areas [15, 31] Although gold dissolution with chlorine is substantially faster than with cyanide, low concentrations of sulphides or other reactive(PDF) Alternatives to cyanide in the gold mining industry:

Extraction of gold from typical Carlin gold concentrate by

2022年2月1日 Most of the gold is encapsulated in sulfides and arsenopyrite in Carlin type gold concentrate; the gold leaching efficiency is less than 8% without pretreatmentCyanide process is a traditional gold leaching method with the disadvantages of several environmental pollution incidents occurred due the breach of tailings disposal In view of 2015年2月1日 Trans Nonferrous Met Soc China 25(2015) 597−607 Treatment of copperrich gold ore by cyanide leaching, ammonia pretreatment and ammoniacal cyanide leaching A D BAS, E KOC, E Y YAZICI, H DEVECI HydrometBPM Group, Division of Mineral Coal Processing, Department of Mining Engineering, Karadeniz Technical Treatment of copperrich gold ore by cyanide leaching, 2020年6月9日 Now, we’re going to talk about the factors affecting gold vat leaching process 1 Cyanide Selection The main cyanides that can be used for gold vat leaching process include: KCN、NaCN、NH4CN 4 Factors Affecting Gold VAT Leaching Process LinkedIn

Advances in the cyanidation of gold ScienceDirect

2005年1月1日 Fig 7 illustrates the benefits of using a high oxygen content in cyanidation of a gold ore with low pyrite and pyrrhotite content (Deschênes et al, 1999) A 16 ppm oxygen concentration in leaching can result in a faster dissolution rate than a 147% increase in the cyanide concentration The use of oxygen has resulted in a 30% reduction in 2010年7月1日 Cyanidation tests on two ore samples from two different gold deposits are reported The first sample contained 105 ppm gold with high arsenic and antimony The second sample had a low gold content (25 ppm) but a high silver content (160 ppm)The first series of test work focused on the determination of conditions for extracting gold Cyanidation of gold ores containing copper, silver, lead, arsenic 2020年11月13日 I Gold Ore Dressing Equipment for Cyanidation 1Zinc Powder Replacement Device The usage of zinc powder/wire to replace gold, is called cyanidezinc replacement process (CCD method and CCF method)Main Equipment for Gold Ore Dressing LinkedIn